2025 Top Trends in Wire Cable Assembly: Essential Insights for Industry Professionals

As we move towards 2025, the wire cable assembly industry is poised to experience significant transformations driven by technological advancements and evolving market demands. According to John Smith, a leading expert in wire cable assembly and senior engineer at Tech Solutions, "The future of wire cable assembly lies in our ability to innovate and adapt to the changing landscape of connectivity." This statement resonates deeply in an industry where precision, reliability, and efficiency are paramount.

In the coming years, experts predict that trends such as automation, the rise of IoT applications, and advancements in materials science will redefine the wire cable assembly landscape. Professionals in this field must stay abreast of these trends to remain competitive and meet the rising expectations of clients. The integration of smart manufacturing practices not only enhances production efficiency but also ensures high-quality standards that are crucial in various applications, from telecommunications to automotive sectors.

As we delve into the top trends shaping wire cable assembly, it is essential for industry professionals to outline strategic approaches that align with these innovations. Understanding these dynamics will enable them to harness opportunities, mitigate challenges, and ultimately, drive their businesses towards sustainable growth in an ever-evolving marketplace.

Emerging Technologies in Wire Cable Assembly for 2025

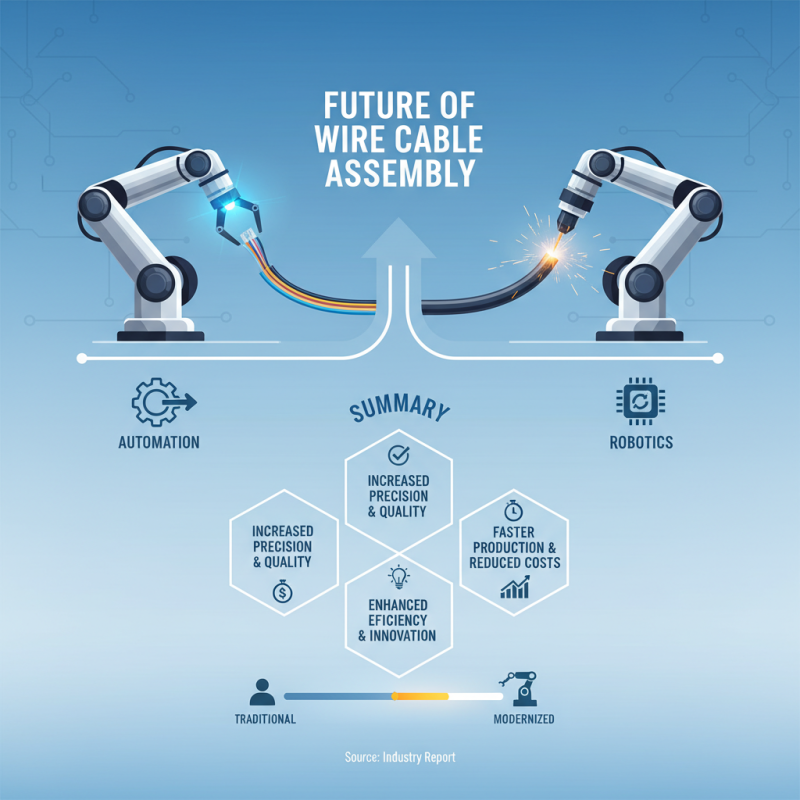

In 2025, the wire cable assembly industry is set to witness transformative changes driven by emerging technologies. Among these, the integration of automation and advanced manufacturing techniques stands out as a pivotal trend. According to a report by industry experts, automated wire harness assembly can increase production efficiency by up to 30%, while also reducing errors associated with manual assembly processes. As companies begin to leverage robotics and artificial intelligence, the demand for skilled professionals who can work alongside these technologies is expected to escalate, highlighting the necessity for continuous training and development in the workforce.

Another significant trend is the rise of smart materials and IoT-enabled cable assemblies. The growing emphasis on connectivity and data transmission has led to enhanced developments in wire and cable designs that can withstand harsher environmental conditions while maintaining high-performance standards. A recent market study predicts that the smart wire and cable segment will witness a compound annual growth rate (CAGR) of over 10% through 2025. This shift towards smarter, more adaptable cable assemblies aligns with the industry's shift towards environmentally sustainable practices and energy efficiency, often required in future-oriented technological applications such as electric vehicles and renewable energy systems. Consequently, industry professionals must stay vigilant and adaptive, embracing these innovations to maintain competitive advantages in an increasingly complex market landscape.

Key Market Drivers Influencing Wire Cable Assembly Trends

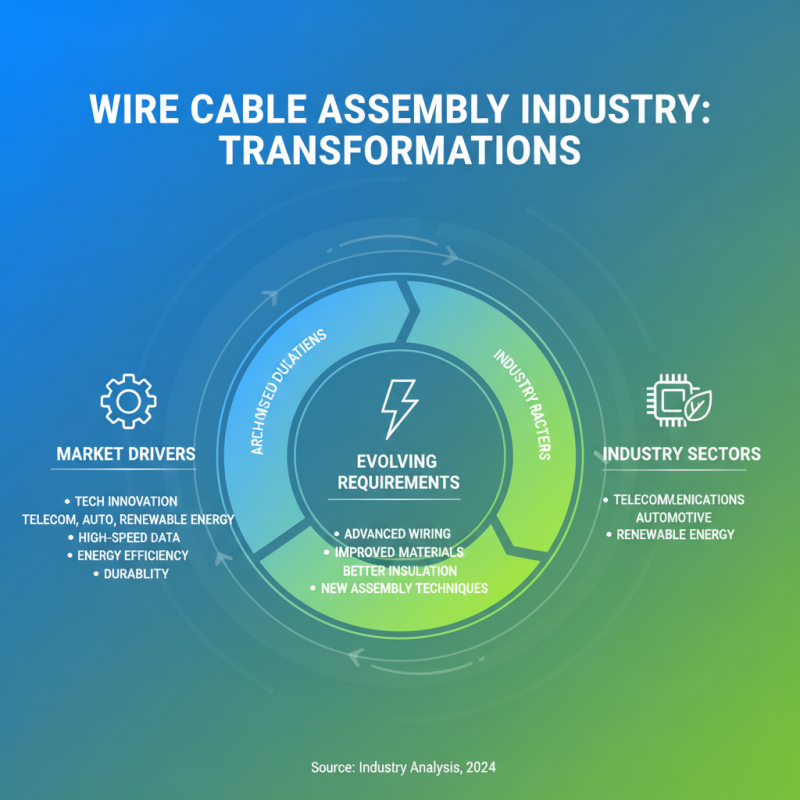

The wire cable assembly industry is undergoing significant transformations driven by various market dynamics. One of the key market drivers is the growing demand for innovation in technology, particularly in sectors such as telecommunications, automotive, and renewable energy. As these industries evolve, there is an increasing requirement for advanced wiring solutions that can support high-speed data transmission, enhance energy efficiency, and provide durability in diverse environmental conditions. This trend necessitates continuous improvements in wire materials, insulation properties, and assembly techniques to meet the rigorous standards set by modern applications.

Another critical factor influencing wire cable assembly trends is the push for sustainability and environmental responsibility. As companies globally strive to reduce their carbon footprints, the demand for eco-friendly materials and manufacturing processes has surged. This shift not only reflects a societal change towards sustainable practices but also drives innovation in the development of biodegradable and recyclable cables. Furthermore, regulatory pressures are prompting manufacturers to adopt greener alternatives, thereby shaping the future landscape of the wire cable assembly industry and emphasizing the importance of sustainable practices in production and design.

Sustainable Practices and Materials in Wire Cable Production

The growing emphasis on sustainability within the wire cable assembly industry is shaping the future of production practices and material selection. As environmental concerns escalate, industry professionals are increasingly looking for innovative ways to reduce their carbon footprint. This includes adopting renewable energy sources in manufacturing processes, enhancing energy efficiency, and minimizing waste. The integration of life cycle assessments into production planning helps companies understand the environmental impact of their products from raw material extraction through to end-of-life disposal, paving the way for more sustainable practices.

In addition to energy efficiency, the materials used in wire cable assembly are undergoing significant transformations. Many companies are exploring biodegradable plastics and recycled metals, thereby reducing reliance on virgin resources. The shift towards these sustainable materials not only addresses environmental concerns but also meets the growing consumer demand for eco-friendly products. By investing in research and development of alternative materials and processing techniques, industry leaders can drive innovation while promoting sustainability in the wire cable assembly sector. This holistic approach not only benefits the planet but also positions companies as responsible players in a rapidly evolving market.

2025 Top Trends in Wire Cable Assembly: Essential Insights for Industry Professionals

| Trend | Description | Impact on Industry | Sustainability Aspect |

|---|---|---|---|

| Eco-friendly Materials | Increased adoption of biodegradable and recyclable materials in cable production. | Reduces environmental footprint and enhances brand reputation. | Utilizes sustainable sourcing practices and lowers waste generation. |

| Smart Cable Technology | Integration of IoT sensors in cables for enhanced monitoring and diagnostics. | Improves operational efficiency and predictive maintenance. | Optimizes resource usage and minimizes energy waste. |

| Automated Production | Increased use of automation and robotics in the manufacturing process. | Enhances production speed and reduces labor costs. | Minimizes material waste through precision engineering. |

| Green Certifications | Increasing importance of obtaining certifications for sustainable practices. | Builds consumer trust and opens new markets. | Promotes environmentally responsible business operations. |

| Circular Economy Approach | Adopting processes that focus on product life-cycle and material recovery. | Encourages recycling and reusing materials. | Helps in resource conservation and waste reduction. |

Impact of Automation and Robotics on Cable Assembly Processes

The convergence of automation and robotics within the wire cable assembly industry marks a significant technological shift that is reshaping manufacturing processes. Automation introduces precision and consistency, streamlining tasks that were traditionally labor-intensive. From wire cutting to crimping and assembly, automated systems can perform these duties faster and with fewer errors than human workers. This shift not only enhances operational efficiency but also reduces production costs, enabling companies to allocate resources to more strategic areas such as research and development.

Robotics takes this transformation a step further by adding a layer of adaptability to the cable assembly process. Advanced robotic technologies can handle complex tasks and adapt to different production needs without significant downtime. For instance, collaborative robots (cobots) work alongside human operators, assisting in tasks that require dexterity and speed while allowing for a more dynamic work environment. This collaboration enhances productivity while ensuring that human expertise is still utilized in critical decision-making processes. As industry professionals navigate these technological advancements, understanding the impact of automation and robotics will be essential for staying competitive in the evolving landscape of wire cable assembly.

Future Demand Projections for Wire Cable Assembly in Various Industries

The demand for wire cable assembly is set to witness significant growth across various industries by 2025. As technological advancements continue to reshape sectors such as telecommunications, automotive, and renewable energy, the integration of sophisticated wire cable systems becomes increasingly essential. In telecommunications, for instance, the expansion of 5G networks is driving the need for high-quality, reliable wire assembly solutions to support faster data transmission and enhanced connectivity. This evolving landscape not only emphasizes the role of wire cable assembly in improving infrastructure but also highlights the industry's responsibility to innovate continually.

In the automotive industry, the rise of electric and autonomous vehicles is further fueling the demand for specialized wire cable assemblies. As vehicles become more complex, incorporating advanced electronics and safety features, manufacturers are seeking tailored solutions that ensure safety and efficiency. Furthermore, the growing emphasis on sustainability is influencing production processes, with companies striving to utilize eco-friendly materials and methods, thus aligning with global environmental goals. As these trends unfold, industry professionals must stay informed about emerging technologies and market dynamics to leverage opportunities and address challenges effectively in the wire cable assembly sector.

Related Posts

-

Challenges Faced in Cable Harness Design Efficiency

-

Explore Superior Wire Harness Assembly Solutions from Leading Chinese Manufacturers

-

The Definitive Ultimate Guide to Mastering Wire Harness Assembly for Optimal Performance

-

Innovative Applications of Molded Cable Assemblies Across Various Industries

-

How to Optimize Your Electrical Harness Assembly for Maximum Efficiency

-

How to Select the Right Electrical Harness Connectors for Your Projects