How to Choose the Right SMA Male Connector for Your Project

Choosing the right SMA male connector for your project is crucial in ensuring optimal performance in RF applications. As the demand for high-frequency and high-performance connectivity components continues to grow, the global RF connector market is projected to reach $3.02 billion by 2026, with a significant share attributed to SMA connectors due to their broad frequency range and excellent durability characteristics. According to industry reports, SMA male connectors are widely recognized for their reliability in demanding environments, making them a preferred choice for telecommunications, aerospace, and automotive sectors. With the increasing complexity of modern electronic systems, selecting the appropriate SMA male connector is essential to minimize signal loss and maintain system efficiency. This guide aims to provide you with essential criteria and considerations to help you make an informed choice, ensuring your project achieves its intended results.

Understanding the Basics of SMA Male Connectors and Their Applications

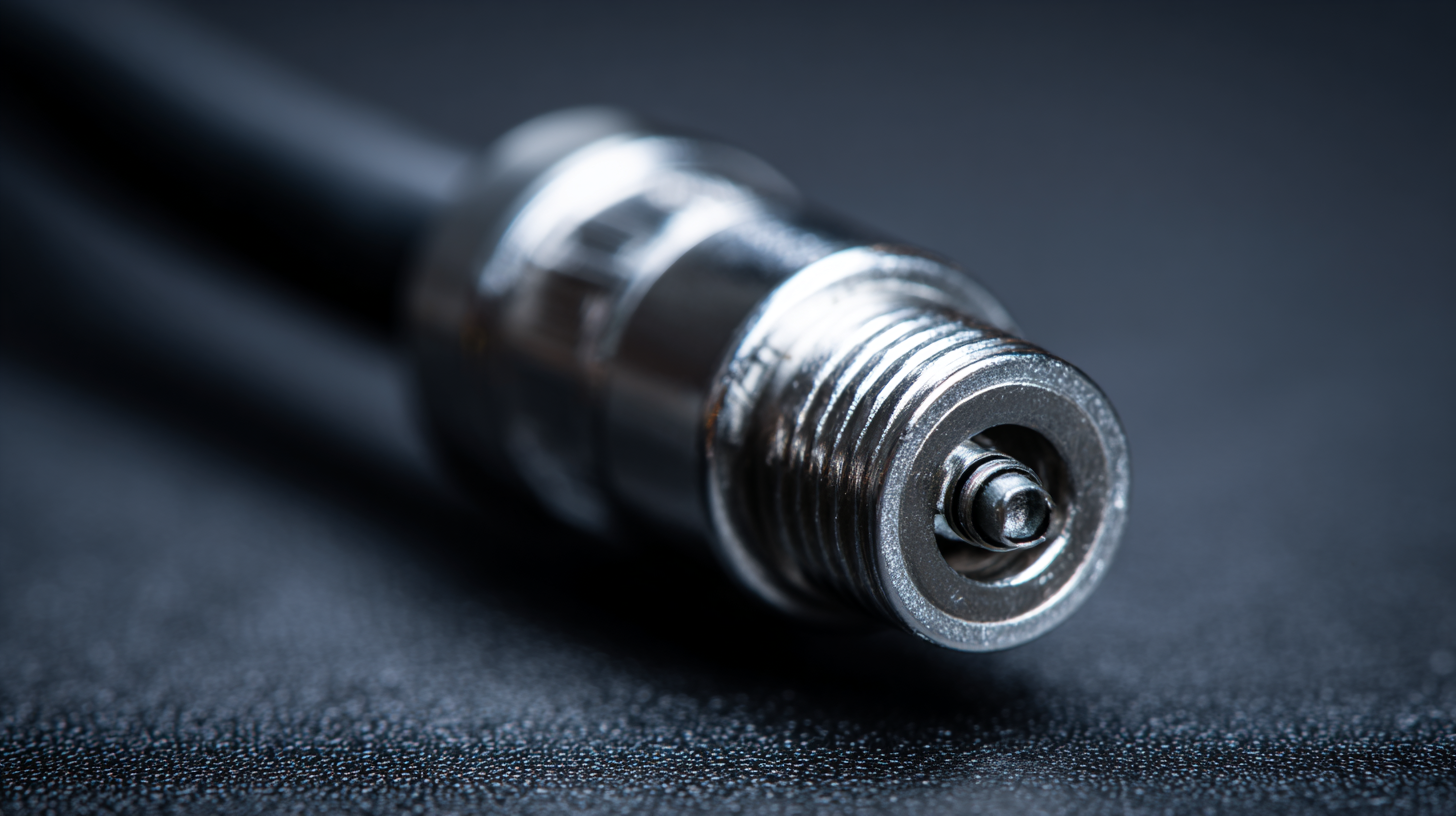

Understanding the basics of SMA male connectors is essential for anyone involved in projects that require RF (radio frequency) applications. SMA connectors, known for their compact size and durability, are widely used in various industries, including telecommunications, aerospace, and satellite communications. These connectors ensure reliable signal transmission and are crucial in maintaining performance standards in high-frequency applications. Knowing the specifications, such as impedance and frequency range, helps in selecting the right SMA male connector for your needs.

When working on a project, consider the specific requirements like environmental conditions and mechanical stress. SMA connectors often come with different plating options and materials suitable for diverse applications. Make sure to assess the cable compatibility and connection type, as these factors can significantly influence your project's success. By understanding these basic principles, you can make informed decisions and improve your project's overall efficiency and performance.

Identifying Key Factors to Consider When Selecting SMA Male Connectors

When selecting the right SMA male connector for your project, it’s crucial to consider various key factors that can significantly impact performance and compatibility. One primary factor is the frequency range. SMA connectors are designed for use in different frequency bands, and selecting a connector that matches the frequency of your application ensures optimal signal transmission. Check the specifications for each connector to guarantee that it meets the requirements of your project.

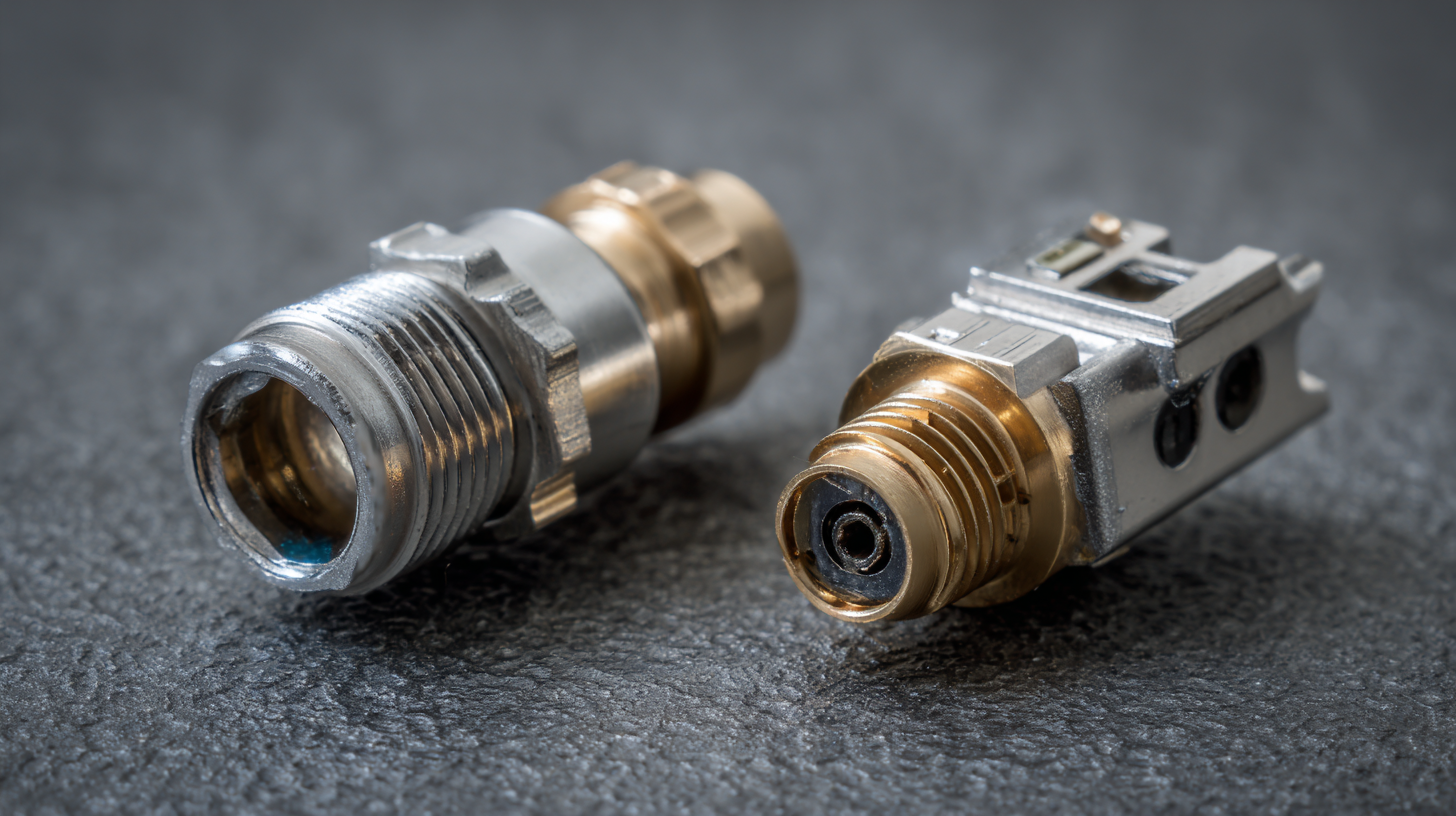

Another important aspect to evaluate is the material and construction quality of the SMA connector. Different materials can affect durability, thermal stability, and overall performance. For instance, connectors made from stainless steel or brass are more resistant to corrosion and can withstand harsher environments. Additionally, the connector's finish, such as gold plating, can enhance conductivity and minimize signal loss, making it essential to choose a connector that aligns with the environmental conditions your project will face. By prioritizing these factors, you can select an SMA male connector that will fulfill your project’s specific needs effectively.

How to Choose the Right SMA Male Connector for Your Project

| Key Factor | Description | Example |

|---|---|---|

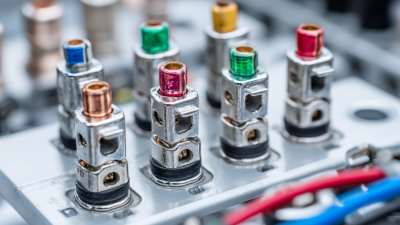

| Connector Type | SMA connectors come in various forms like straight, angled, and bulkhead. | Straight SMA Connector |

| Frequency Range | Ensure the connector supports the frequency range required for your application. | DC to 18 GHz |

| Impedance | Most SMA connectors have a standard impedance of 50 ohms. | 50 Ohm SMA Connector |

| Material | Check materials used for durability and corrosion resistance, such as brass or stainless steel. | Brass with Gold Plating |

| Connector Size | Consider the space available in your project for the connector size. | Standard SMA size: 1.5 inches |

| Frequency Stability | Look for connectors that maintain performance across varying temperatures. | Low Drift SMA Connectors |

Comparing Different SMA Male Connector Types for Specific Use Cases

When selecting an SMA male connector for your project, it's crucial to consider the specific application to ensure optimal performance. Different types of SMA connectors, such as precision SMA, 50-ohm, and 75-ohm variants, are tailored for distinct use cases. For instance, precision SMA connectors are designed for high-frequency applications, offering minimal signal loss and excellent stability. The market for high-frequency connectors is projected to reach $3.1 billion by 2025, underscoring the importance of choosing the right connector for your needs.

In addition to type variations, it’s essential to consider factors like environmental resilience and compatibility with other components. For example, connectors intended for outdoor use should have enhanced weatherproofing features. A study from the Electronic Industry Association indicates that over 30% of connector failures are due to environmental damage, making material selection critical.

Tips: Always refer to the connector's specifications, such as frequency range and VSWR (Voltage Standing Wave Ratio), when evaluating options. Additionally, investing in connectors with a proven track record in similar applications can significantly reduce potential issues down the line. Finally, don't overlook user reviews or industry comparisons, as they can provide insights that technical datasheets may not reveal.

Evaluating Quality and Performance Standards in SMA Male Connectors

When selecting an SMA male connector for your project, understanding quality and performance standards is crucial. SMA connectors are commonly used in RF applications where reliable connections are essential. To ensure optimal performance, look for connectors that follow industry standards such as MIL-STD or IEC specifications. These standards help guarantee the connectors will provide consistent electrical performance, low signal loss, and durability under various environmental conditions.

In addition to adhering to established standards, it's important to evaluate the materials used in the manufacturing of SMA male connectors. High-quality materials like brass and gold plating can significantly enhance signal integrity and reduce the risk of corrosion. Performance metrics such as VSWR (Voltage Standing Wave Ratio) and insertion loss should also be assessed, as they indicate how well the connector will perform in actual use. By prioritizing both quality materials and recognized performance standards, you can select an SMA male connector that meets the specific demands of your project and ensures a reliable connection.

Guidelines for Sourcing and Purchasing SMA Male Connectors for Projects

When sourcing and purchasing SMA male connectors for your project, it is crucial to consider several key factors to ensure compatibility and performance. First, assess the frequency range of your application. SMA connectors are commonly utilized in RF applications up to 18 GHz, but certain specialized versions can handle frequencies up to 26.5 GHz. According to a recent market report by MarketsandMarkets, the RF connectors market is expected to grow from USD 3.54 billion in 2020 to USD 6.92 billion by 2025, highlighting the increasing demand for high-frequency connectors in various industries, including telecommunications and automotive sectors.

When sourcing and purchasing SMA male connectors for your project, it is crucial to consider several key factors to ensure compatibility and performance. First, assess the frequency range of your application. SMA connectors are commonly utilized in RF applications up to 18 GHz, but certain specialized versions can handle frequencies up to 26.5 GHz. According to a recent market report by MarketsandMarkets, the RF connectors market is expected to grow from USD 3.54 billion in 2020 to USD 6.92 billion by 2025, highlighting the increasing demand for high-frequency connectors in various industries, including telecommunications and automotive sectors.

Another important aspect is the material and construction of the SMA male connectors. Look for connectors made from high-quality materials such as brass or stainless steel, which provide better durability and resistance to corrosion. The plating finish, typically gold or nickel, can significantly affect performance metrics like signal integrity and longevity. A study from Research and Markets indicates that the performance reliability of connectors, including SMA types, can decrease by up to 40% if substandard materials are used, underscoring the importance of selecting connectors that meet industry standards. Always verify that the connectors comply with applicable regulations and certifications, which can contribute to overall project success.

Related Posts

-

What You Need to Know About SMA Male Connectors for Your Next Project

-

Essential Harness Assembly Checklist for Streamlined Production Efficiency

-

What is a Cable Wire Harness and How Does It Power Modern Innovations?

-

The Ultimate Guide to Streamlining Your Harness Assembly Process for Maximum Efficiency

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier

-

How to Choose the Right Wire Terminals for Optimal Electrical Performance: Expert Insights and Data