2026 How to Choose the Right Cable and Harness for Your Needs?

Choosing the right cable and harness is crucial for various applications. With numerous options available, it can feel overwhelming. Understanding your specific requirements is essential. The right cable and harness ensure proper functionality and safety.

When selecting cable and harness combinations, consider factors like material, flexibility, and temperature resistance. These elements directly impact performance. Visualize the environment where they will be used. Will they be exposed to harsh conditions?

Mistakes can be costly. Choosing the wrong cable and harness might lead to failures. Take time to evaluate your choices. Gather information from reliable sources. Reflect on your needs to make informed decisions. Embrace the complexity of selection for the best outcomes.

Understanding Your Electrical Requirements for Cables and Harnesses

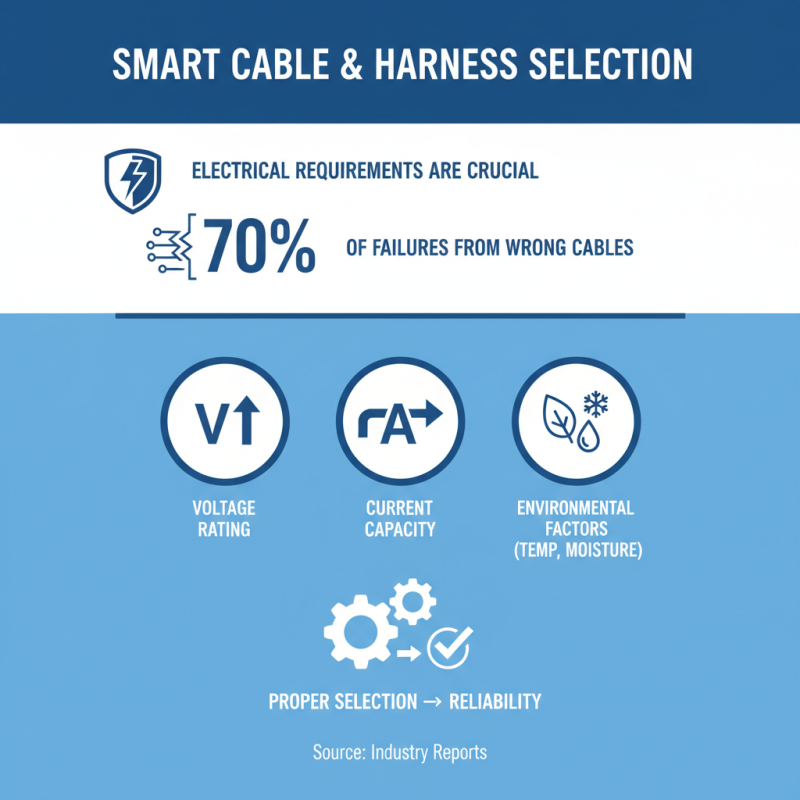

When selecting cables and harnesses, one must consider specific electrical requirements. Electrical specifications guide the choice of materials and designs. According to industry reports, over 70% of electrical failures are linked to improper cable selection. Understanding voltage, current capacity, and environmental factors is vital.

Voltage ratings determine the maximum load a cable can handle. Using a cable beyond its capacity leads to overheating. Current capacity impacts how much power can be safely transmitted. If a cable cannot support the needed current, it may fail. Regular testing can prevent these issues. But many overlook this step.

Environmental conditions also play a role. Temperature, humidity, and exposure to chemicals impact cable performance. For instance, cables in harsh conditions require better insulation and durability. Awareness of these factors is essential. Misjudgments can lead to costly repairs. Investing time in understanding these requirements pays off.

Types of Cables and Harnesses Available in the Market

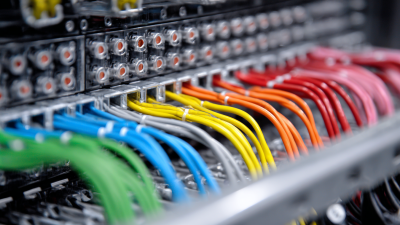

When choosing the right cable and harness, it's essential to understand the different types available on the market. Cables come in various forms, including power cables, data cables, and coaxial cables. Each type serves a specific purpose and offers unique features. Power cables carry electrical current, while data cables transmit information. Coaxial cables are often used for television and internet connections.

Harnesses, on the other hand, organize multiple cables into a single unit. They help reduce clutter and improve efficiency. Wire harnesses can be customized for specific needs. They often include connectors that ensure secure connections. Flexibility in design allows for tailored solutions.

Tips: Always check the voltage rating. It’s crucial for safety. Consider the length of cables too. Excess length can lead to signal loss. Lastly, balance between cost and quality is vital. Cheaper options might not last, while high-end choices may not be necessary. Testing cables before finalizing your decision can prevent issues later.

2026 How to Choose the Right Cable and Harness for Your Needs?

| Type of Cable | Usage | Material | Max Voltage | Temperature Rating |

|---|---|---|---|---|

| Coaxial Cable | Data Transmission | Copper, Plastic | 75 V | -40°C to 85°C |

| Fiber Optic Cable | High-Speed Internet | Glass, Plastic | Variable | -40°C to 70°C |

| Twisted Pair Cable | Telecommunications | Copper | 2.5 V | -20°C to 60°C |

| PVC Cable | General Wiring | Copper, PVC | 300 V | -10°C to 90°C |

| Silicone Wire | High-Temperature Applications | Copper, Silicone | 600 V | -60°C to 200°C |

Key Factors to Consider When Selecting Cables and Harnesses

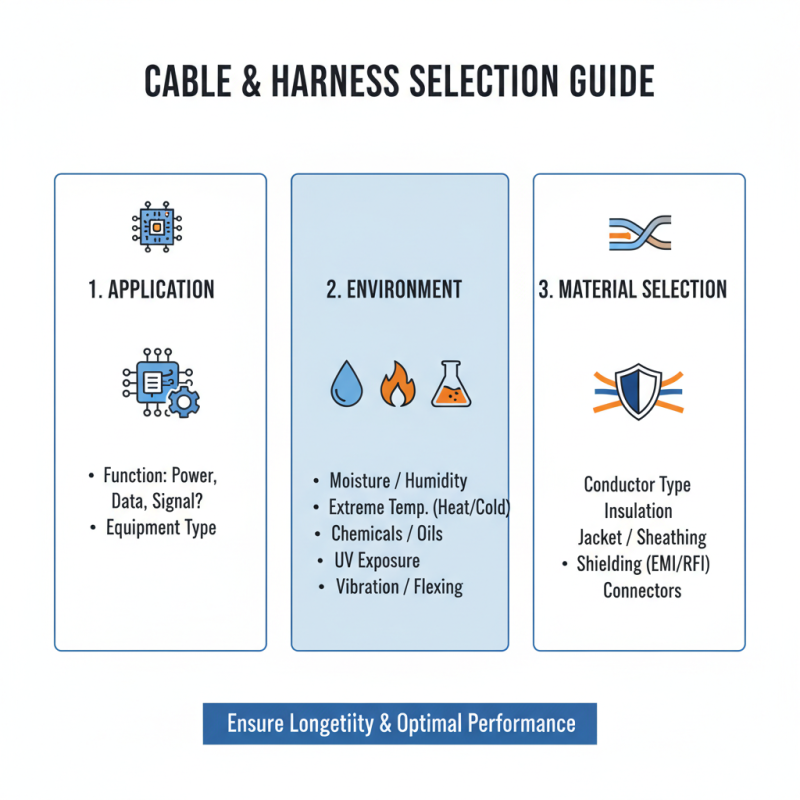

When choosing cables and harnesses, several factors demand your attention. Identify the specific application for which you need these components. The environment plays a crucial role. For instance, will they be exposed to moisture, heat, or chemical substances? These situations require specialized materials to ensure longevity and performance.

Consider the gauge and type of wires. Thicker wires can handle more current but may be less flexible. Think about flexibility if your application involves tight spaces or dynamic movement. Additionally, pay attention to the insulation. A poor choice here can lead to failures and costly downtime.

Lastly, do not ignore the connectors. They must fit well and provide reliable connections. A mismatch here can compromise the entire system. Remember, it’s the little details that often cause the biggest headaches. Regularly review your choice and seek improvements, as the best solutions evolve with your needs.

Compatibility and Standards: Ensuring Proper Fit and Functionality

Choosing the right cable and harness is crucial for many applications. However, ensuring compatibility and adhering to standards can often be a challenge. Each project might require different specifications. This can lead to confusion, especially when multiple options are available. It’s essential to consider the technical requirements, such as voltage and current rating.

Compatibility starts with understanding the connectors and fittings. Not all cables fit all harnesses. Mismatched components can lead to poor performance or even system failures. Sometimes, even minor differences in wiring can cause issues. Having a clear list of required specifications can help narrow down choices.

Industry standards help in determining fit and functionality. Understanding these standards can reduce mistakes. However, even with standards in place, human errors occur during installation. It’s important to verify connections after assembly. Feedback from previous projects can help improve future choices. Ultimately, careful planning and adherence to compatibility will lead to better performance in your application.

2026 Cable and Harness Selection Trends

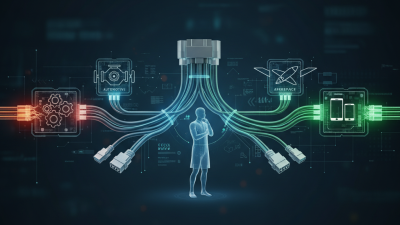

Common Applications and Use Cases for Cables and Harnesses

When selecting cables and harnesses, understanding their applications is crucial. These components serve various industries, including automotive, aerospace, and telecommunications. For example, in the automotive sector, wiring harnesses manage power distribution. They ensure vehicles run smoothly and efficiently. A study indicated that harnesses account for nearly 20% of vehicle assembly time.

Tips: Assess your specific application. Identify the environment where the cable will be used. Harsh conditions require robust materials.

Another common use for cables and harnesses is in consumer electronics. These devices rely on reliable connections for performance. Poorly designed cables can lead to failures and dissatisfaction. According to research, 30% of electronic malfunctions stem from poor wiring.

Tips: Don't overlook testing. Always check your cables for performance before installation. This step can save time and money later.

Related Posts

-

Top 10 Reasons to Choose the Right Harness Cable Assembly for Your Project

-

The Ultimate Guide to Streamlining Your Harness Assembly Process for Maximum Efficiency

-

What is a Cable Wire Harness and How Does It Power Modern Innovations?

-

Revolutionizing Your Production: The Future of Wire Harness Design and Its Impact on Manufacturing Efficiency

-

The Definitive Ultimate Guide to Mastering Wire Harness Assembly for Optimal Performance

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier