How to Choose the Right Cable Wire Harness for Your Project?

Choosing the right cable wire harness for your project is crucial. A well-designed harness ensures efficiency and reliability. It connects various electrical components seamlessly. The right choice can prevent delays and increase the lifespan of your equipment.

Consider the specific requirements of your project. Different applications demand different configurations. Taking measurements and understanding the environment can be challenging. You may overlook certain details that impact performance. Always factor in flexibility and durability.

Quality matters when selecting a cable wire harness. Cheaper options can lead to failures. Investing in a reliable harness pays off in the long run. Reflections on previous choices can guide your decisions. Avoid repeating mistakes by learning from past experiences.

Understanding Cable Wire Harness Types and Their Applications

When embarking on a project involving cable wire harnesses, it's crucial to understand the different types available. A cable wire harness can vary significantly in design and application. For instance, there are custom harnesses tailored for specific devices like medical equipment or automotive systems. These harnesses often enhance performance and ensure safety.

Flexible harnesses are another option, ideal for tight spaces. They can bend and twist without damaging the wires inside. On the other hand, heat-resistant harnesses are necessary for high-temperature environments. Choosing the right type may seem straightforward, but it's often a complex decision. Engineers must consider factors like material, insulation, and environmental conditions.

Often, mistakes can occur if one hastily selects a harness without thorough analysis. Each project's unique demands should dictate the choice. A harness that works perfectly for one application might fail in another. Therefore, taking the time to explore and evaluate options is an essential step that cannot be overlooked. Mistakes will be learning opportunities, leading to better decision-making in future projects.

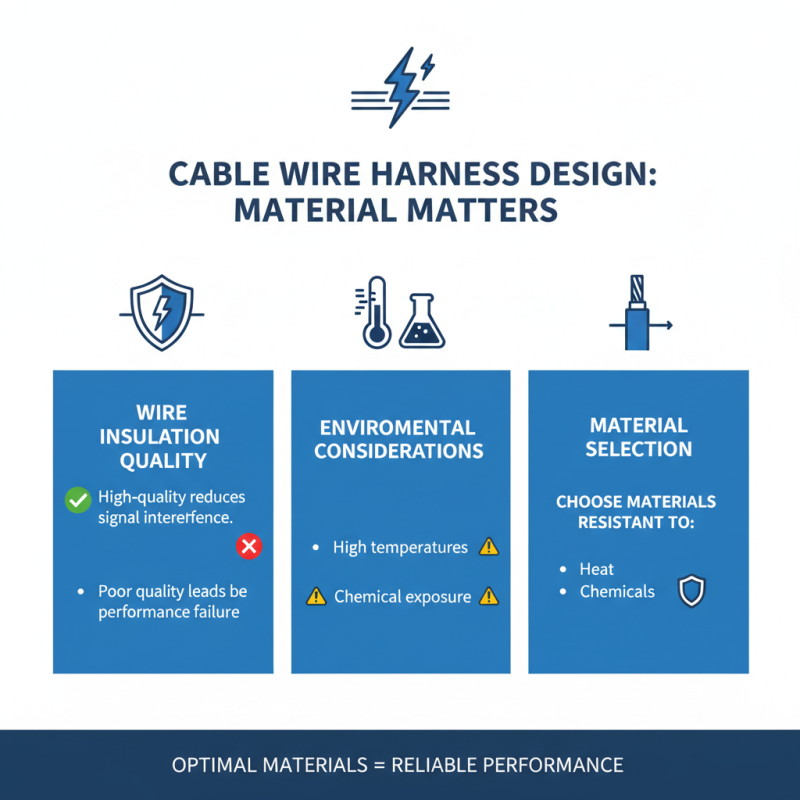

Key Factors in Cable Wire Harness Design for Optimal Performance

When designing a cable wire harness, the materials used play a crucial role. Selecting high-quality wire insulation can reduce signal interference. Poor insulation may lead to failure in performance. Consider the environment where the harness will be used. High temperatures or exposure to chemicals can deteriorate materials quickly. Opt for wire types that can withstand these conditions.

The layout of the harness is equally important. A well-organized wire harness eases installation and maintenance. Bundling wires too tightly can lead to overheating. Ensure there is enough space for movement and expansion. Using appropriate connectors will enhance the reliability of the harness. Conversely, using low-quality connectors might result in intermittent connections.

Thinking about future upgrades is also essential. Design the harness with flexibility in mind. This can save time and cost if modifications are needed later. Regular reviews of the design process can highlight areas for improvement. Reflecting on past projects might uncover mistakes and lead to better decisions.

Assessing Material Choices for Durability and Flexibility in Harnesses

When selecting a cable wire harness, material choice is crucial.

Durability often comes from materials like PVC and nylon. These options resist wear and environmental stress. Also, they may offer varying degrees of flexibility. A more flexible harness can be easier to install but may lack the durability needed. It’s a balance that requires careful consideration.

Consider the project's specific environment. For outdoor applications, UV resistance might be vital. If the environment involves high temperatures, heat-resistant materials could be essential. Testing material in real-world conditions can provide insights. Sometimes, the theoretical benefits don’t translate well in practice.

Reflections on prototypes can guide decisions. Pay attention to how the harness performs in different scenarios. Observations during use reveal imperfections. Materials might fail where you least expect. Taking notes on these observations prepares you better for future projects.

Analyzing Connector Options for Enhanced Electrical Connectivity

When selecting a cable wire harness, the choice of connectors is vital. Connectors serve as the interface between your harness and other devices. An ideal connector should match the project's specifications. They influence signal integrity and power delivery. Various connector types exist. Each comes with unique features that can make or break your project.

Consider the environment where the connectors will be used. Will they face moisture? What about extreme temperatures? These factors affect durability and performance. Each connector has ratings for temperature, vibration, and moisture resistance. Choosing a connector that doesn’t suit your setting can lead to failure.

Look at size and pin configuration as well. A connector may fit physically but may not transmit power effectively. You might end up with unstable connections if you overlook this. Sometimes, simpler designs work better than complex ones. Reflect on your project needs carefully. Choose connectors that enhance connectivity without complicating the system. Avoid errors that require costly fixes later.

How to Choose the Right Cable Wire Harness for Your Project? - Analyzing Connector Options for Enhanced Electrical Connectivity

| Connector Type | Pin Count | Current Rating (Amps) | Wire Gauge | Housing Material | Application Area |

|---|---|---|---|---|---|

| Molex Connector | 4 | 5 | 22 AWG | Plastic | Consumer Electronics |

| DEUTSCH Connector | 2 | 20 | 16 AWG | Thermoplastic | Automotive |

| JST Connector | 3 | 2 | 26 AWG | Nylon | Robotics |

| XLR Connector | 3 | 10 | 20 AWG | Metal | Audio Equipment |

| RJ45 Connector | 8 | 1 | 24 AWG | Plastic | Networking |

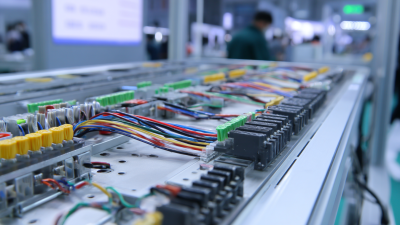

Evaluating Production Techniques to Reduce Lead Time and Costs

When choosing the right cable wire harness for your project, evaluating production techniques is essential.

The method of assembly can greatly influence both lead time and costs. For instance, automated processes may speed up production, but they come with high setup costs. On the other hand, manual assembly tends to be slower but may save money in initial stages. Balancing speed and budget requires careful analysis.

Consider the materials used. Using high-quality wires can prevent future issues, yet they may increase immediate costs. It's vital to assess whether the long-term benefits outweigh the initial investment. Are you prepared to handle potential delays? Look at your timeline. If deadlines are tight, cheaper alternatives might lead to compromises later. Reflect on your project's objectives; they should guide your choice of production technique.

Every project has its unique challenges. Perhaps you have limited resources or you’re facing a tight schedule. These factors should inform your decisions. Remember, there is often no perfect solution. A thorough evaluation involves weighing advantages against drawbacks. Ultimately, the approach you choose should align with your project's goals while addressing these complicated considerations. All decisions come with risks, and reflecting on those will aid in making a more informed choice.

Related Posts

-

Top 10 Reasons to Choose the Right Harness Cable Assembly for Your Project

-

Exploring Cable and Harness Assembly Innovations at the 138th China Import and Export Fair 2025

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier

-

What is a Cable Harness? Exploring Its Role in Modern Connectivity and Industry Applications

-

2026 How to Choose the Right Cable and Harness for Your Needs?

-

Innovative Applications of Molded Cable Assemblies Across Various Industries