How to Choose the Right Wire Terminals for Optimal Electrical Performance: Expert Insights and Data

Choosing the right wire terminals is crucial for ensuring optimal electrical performance in various applications, from residential wiring to industrial setups. According to a report by the International Electrotechnical Commission (IEC), improper selection of wire terminals can lead to increased electrical resistance, causing overheating and potential failures in systems. In fact, a study by the National Electrical Manufacturers Association (NEMA) revealed that up to 30% of electrical failures can be traced back to inadequate or faulty connections at terminals. Given the critical role that wire terminals play in maintaining efficient current flow and overall safety, it's essential for professionals and enthusiasts alike to understand the key factors that influence their performance. This blog aims to provide expert insights and data to help you navigate the complexities of choosing the most suitable wire terminals for your specific needs.

Key Factors to Consider When Selecting Wire Terminals for Your Project

When selecting wire terminals for your electrical project, several key factors must be considered to ensure optimal performance. First, it's crucial to evaluate the wire gauge compatibility. Different terminals are designed for specific wire sizes, and using incorrect gauge sizes can lead to inefficient connections or even failures. Always check the terminal specifications and ensure they match the wire gauge being used to maintain a reliable connection.

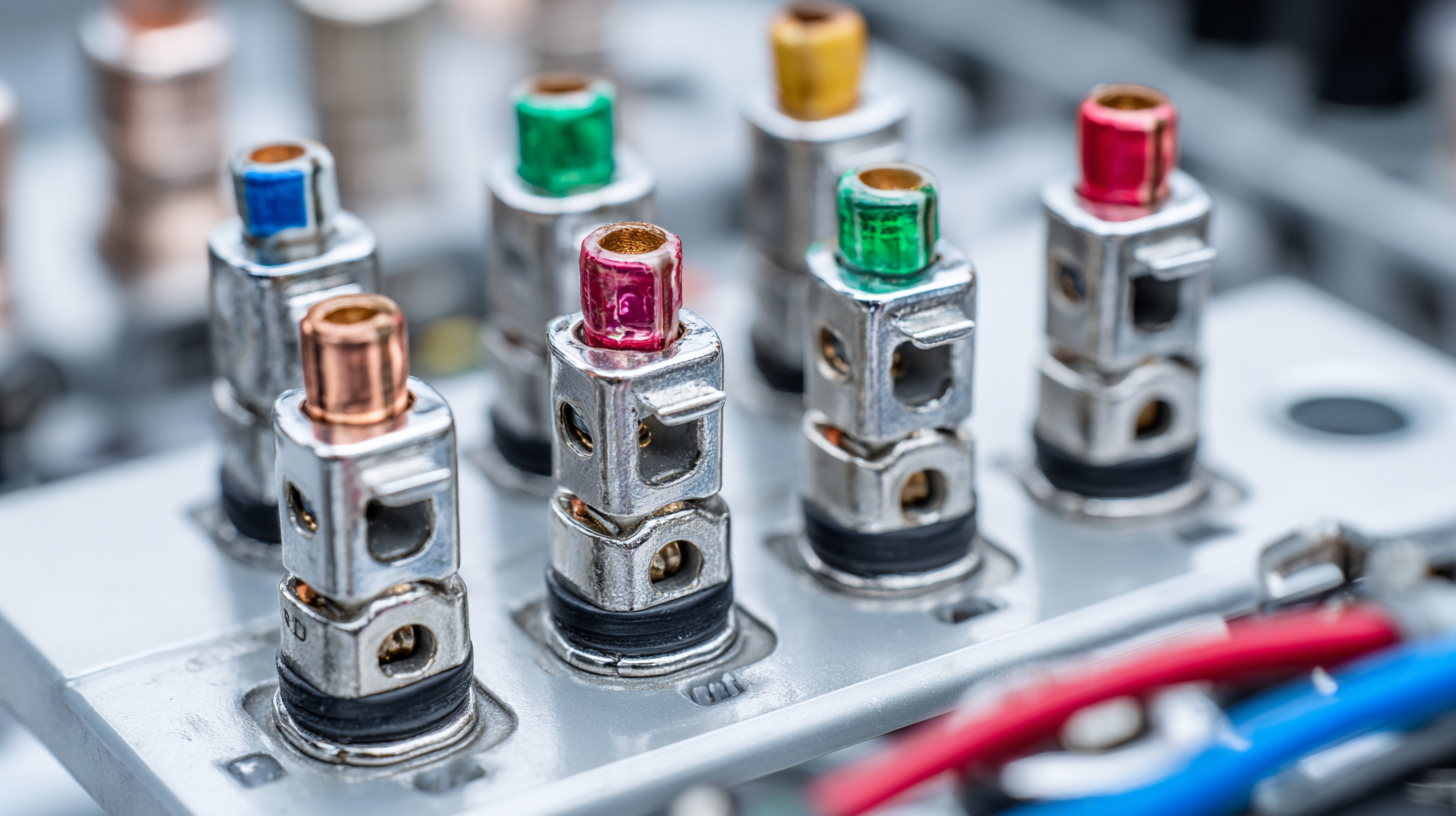

Another important consideration is the terminal material. Common materials include copper and aluminum, each possessing unique properties that affect conductivity and corrosion resistance. Copper terminals offer superior conductivity and are often preferred for high-performance applications, while aluminum may be more suitable for certain outdoor or industrial settings due to its lightweight and rust-resistant characteristics. Additionally, consider environmental factors like temperature and humidity levels in your application, as these can impact terminal longevity and reliability. Selecting the right materials and specifications will significantly impact the efficiency and safety of your electrical systems.

Choosing the Right Wire Terminals for Optimal Electrical Performance

This chart illustrates the performance of different types of wire terminals across various criteria. The metrics assessed include conductivity, durability, and ease of installation, which are key factors to consider when choosing wire terminals for electrical projects.

Understanding Different Types of Wire Terminals and Their Applications

Wire terminals are crucial components in electrical systems, ensuring efficient connectivity and performance. Understanding the different types of wire terminals is essential for selecting the right one for specific applications. According to a recent industry report, improper terminal selection can lead to a 30% increase in failure rates for electrical connections, emphasizing the importance of informed choices.

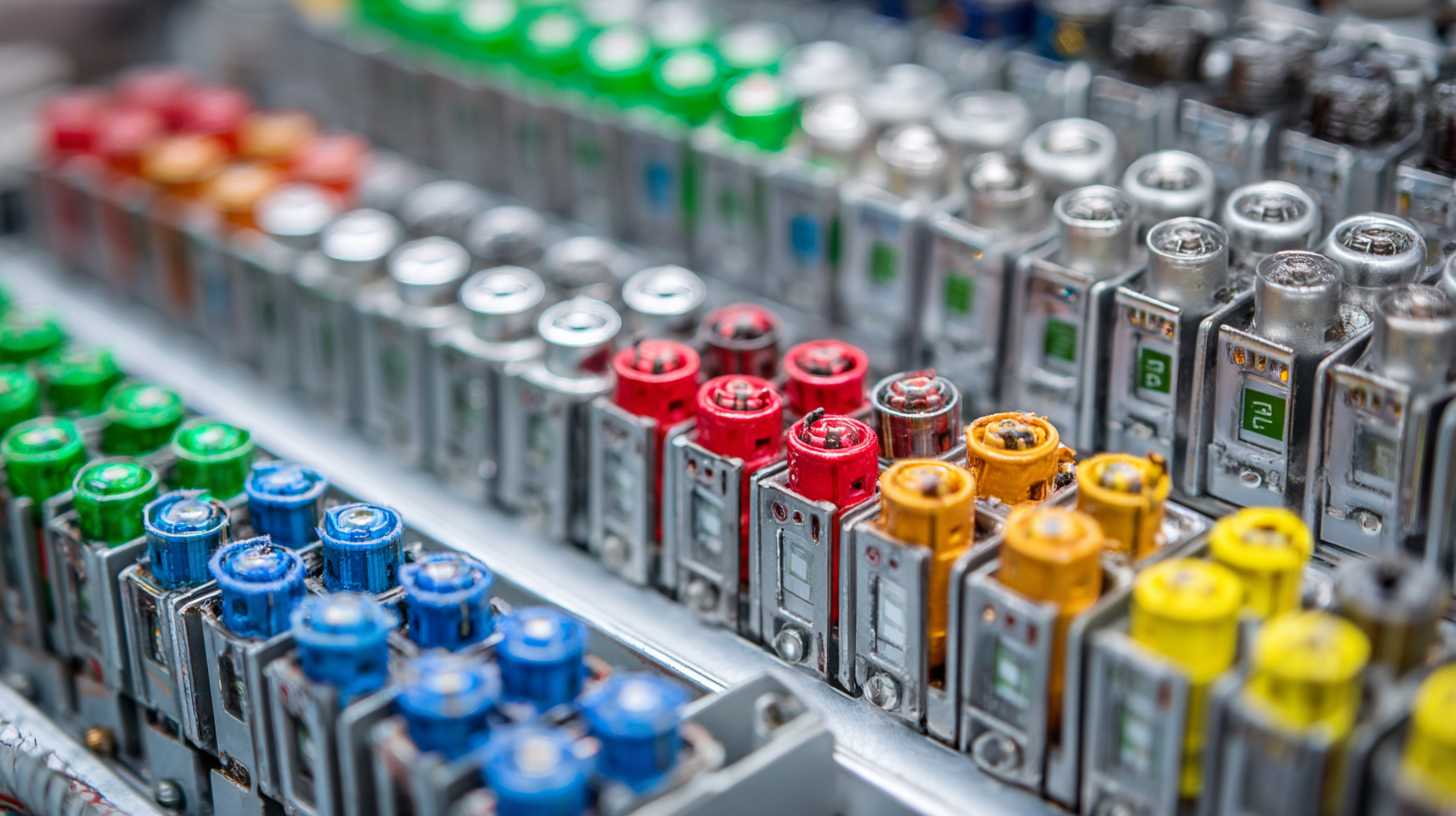

There are several wire terminal types, including ring terminals, spade terminals, and butt connectors, each with unique applications. For instance, ring terminals are ideal for connections requiring a secure and stable attachment, often used in battery and grounding applications where vibration is a concern. Conversely, spade terminals are frequently employed in situations where frequent disconnection is necessary, such as automotive wiring, due to their ease of use. Data indicates that using appropriate terminals can reduce maintenance costs by up to 40%, highlighting their significance in ensuring long-term reliability.

Moreover, selecting the right terminal material is critical. Copper terminals offer excellent conductivity, while aluminum terminals are lighter and more cost-effective. Industry studies show that copper terminals can improve connection resistance by 20% compared to aluminum, making them a preferred choice in high-performance applications. Understanding these distinctions not only enhances electrical performance but also contributes to overall system longevity and efficiency.

The Importance of Material Choices in Wire Terminal Performance

When selecting wire terminals for electrical applications, the choice of materials is critical for ensuring optimal performance and reliability. Different materials offer varying conductivity, corrosion resistance, and thermal stability, which can significantly impact the overall efficiency of electrical connections. For instance, copper terminals are renowned for their excellent conductivity, making them ideal for high-performance applications. However, they may be prone to oxidation, which can hinder performance over time if not properly treated or maintained.

When selecting wire terminals for electrical applications, the choice of materials is critical for ensuring optimal performance and reliability. Different materials offer varying conductivity, corrosion resistance, and thermal stability, which can significantly impact the overall efficiency of electrical connections. For instance, copper terminals are renowned for their excellent conductivity, making them ideal for high-performance applications. However, they may be prone to oxidation, which can hinder performance over time if not properly treated or maintained.

Alternatively, aluminum terminals present a lightweight, cost-effective option, particularly in larger installations. While aluminum offers decent conductivity, it is essential to ensure that they are properly crimped to minimize resistance and avoid failures. Additionally, factors like environmental exposure and the presence of contaminants should inform your selection, as certain materials perform better in harsh conditions. By carefully considering the material properties of wire terminals, professionals can make informed decisions that enhance electrical performance and decrease the likelihood of connection failures.

How to Determine the Best Gauge Size for Optimal Connectivity

Choosing the right gauge size for wire terminals is crucial for ensuring optimal connectivity and electrical performance. According to the American Wire Gauge (AWG) standards, the wire gauge directly affects the current-carrying capacity, with lower numbers indicating thicker wires. For instance, a 12 AWG wire can handle up to 20 amps, while a 14 AWG wire is limited to 15 amps. This difference underlines the importance of selecting the appropriate gauge based on the specific application and load requirements.

Moreover, a report by the National Electrical Manufacturers Association (NEMA) highlights that improper gauge sizes can lead to increased resistance and heat loss, ultimately reducing energy efficiency. In high-demand scenarios, such as industrial applications, the consequences of using the wrong gauge can be significant, potentially resulting in equipment failure or even fire hazards. A thorough understanding of how gauge size correlates with conductivity and overall system performance is essential. The right selection not only enhances safety but also prolongs the lifespan of electronic components, making it a critical consideration for both professionals and DIY enthusiasts alike.

How to Choose the Right Wire Terminals for Optimal Electrical Performance: Expert Insights and Data

| Wire Gauge (AWG) | Diameter (mm) | Current Rating (Amps) | Terminal Type | Recommended Application |

|---|---|---|---|---|

| 14 AWG | 1.63 | 15 | Ring Terminal | Automotive Wiring |

| 16 AWG | 1.29 | 10 | Spade Terminal | Household Appliances |

| 18 AWG | 1.02 | 8 | Bullet Terminal | Low Power Devices |

| 20 AWG | 0.81 | 5 | Connector Terminal | LED Lighting |

| 22 AWG | 0.64 | 3 | Push-On Terminal | Signal Wiring |

Common Mistakes to Avoid When Choosing Wire Terminals

When selecting wire terminals, one of the most common mistakes is overlooking the specific requirements of your electrical project. Many individuals tend to choose terminals based solely on size or appearance, neglecting critical factors such as current ratings, wire gauge compatibility, and environmental conditions. For instance, using a terminal that doesn't match the gauge of the wire can lead to poor connections and potential electrical failures. It’s essential to review the specifications recommended for your specific application to ensure both safety and performance.

When selecting wire terminals, one of the most common mistakes is overlooking the specific requirements of your electrical project. Many individuals tend to choose terminals based solely on size or appearance, neglecting critical factors such as current ratings, wire gauge compatibility, and environmental conditions. For instance, using a terminal that doesn't match the gauge of the wire can lead to poor connections and potential electrical failures. It’s essential to review the specifications recommended for your specific application to ensure both safety and performance.

Another frequent pitfall is disregarding the material composition of the terminals. Not all terminals are created equal; materials such as copper, aluminum, or even steel can significantly affect performance. Copper terminals, for example, provide excellent conductivity but may corrode in harsh environments if not properly coated. Likewise, choosing terminals without considering their insulation properties can result in short circuits or electrical hazards. Therefore, it is vital to conduct thorough research and opt for terminals that are designed for the conditions they will face, ensuring reliable and efficient electrical connections.

Related Posts

-

What is a Cable Wire Harness and How Does It Power Modern Innovations?

-

What You Need to Know About SMA Male Connectors for Your Next Project

-

What Is the Future of Wire Harness Manufacturing Equipment

-

Essential Harness Assembly Checklist for Streamlined Production Efficiency

-

Challenges Faced in Cable Harness Design Efficiency

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier