10 Essential Tips for Choosing the Right SMA Male Connector for Your Project

In the ever-evolving landscape of RF connectors, the SMA male connector stands out as a crucial component in ensuring reliable signal transmission across a variety of applications. According to a report by the International Society of Automation, the RF connector market is projected to reach $3 billion by 2025, driven by advancements in telecommunications and IoT devices. With such significant growth, choosing the right SMA male connector becomes paramount for engineers and designers to optimize performance in their projects.

Dr. John Harrington, a leading expert in RF connectivity solutions, emphasizes the importance of careful selection: "The right SMA male connector can make all the difference in maintaining signal integrity and minimizing losses." As projects increasingly demand higher frequencies and more robust performance, understanding the specifications, compatibility, and environmental requirements of SMA male connectors is critical. This guide aims to provide essential tips to navigate the complexities of selecting the proper SMA male connector for various applications, ensuring that the needs of the project are met without compromise.

Understanding the Basics of SMA Male Connectors for Your Project

When embarking on a project that requires SMA male connectors, it’s crucial to understand their fundamental attributes. SMA (SubMiniature version A) connectors are widely used in RF applications due to their superior performance in the microwave frequency range up to 18 GHz. They are known for their robustness and compact design, making them ideal for communication systems, satellite dish installations, and various electronic devices. Industry reports indicate that the global RF connector market is projected to reach approximately $3 billion by 2025, reflecting the growing importance of efficient connectivity in technology.

One essential tip when choosing an SMA male connector is to consider the application environment. For outdoor or harsh conditions, select connectors that feature weather-sealed or waterproof designs to ensure longevity and reliable performance. Additionally, it’s vital to assess the connector's impedance, typically 50 ohms for SMA connectors, to guarantee optimal signal integrity and minimize reflection losses. According to a recent industry analysis, improperly matched impedance can lead to transmission losses exceeding 20%, significantly impacting system performance.

Lastly, always check the material composition of the connector. High-quality connectors are often made with materials such as brass or stainless steel, offering better durability and resistance to corrosion. Ensure that the connector meets the specific standards required for your project, ideally aligning with MIL-STD specifications for reliability. Selecting the right SMA male connector not only enhances the performance of your project but also ensures scalability for future expansions.

Key Specifications to Consider When Choosing SMA Male Connectors

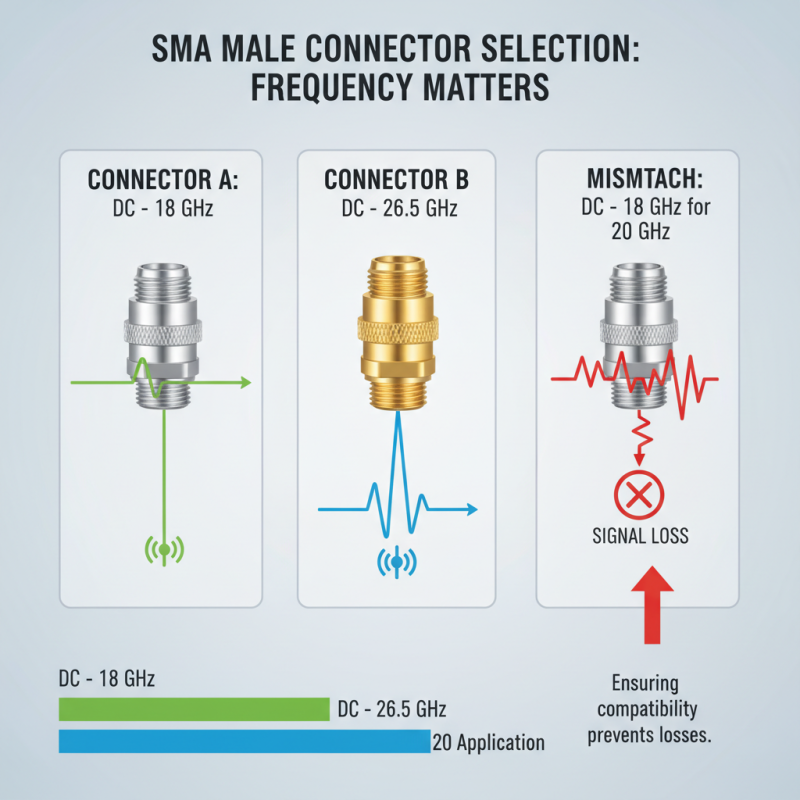

When selecting the right SMA male connector for your project, it is essential to consider several key specifications that can significantly influence performance and compatibility. One of the primary factors is the frequency range of the connector. SMA connectors are typically designed for microwave frequencies, commonly ranging from DC to 18 GHz, but some can even handle up to 26.5 GHz. Ensuring that your chosen connector can support the necessary frequency range for your application will prevent losses and maintain signal integrity.

Another critical specification is the connector’s impedance, which is typically 50 ohms for RF applications and 75 ohms for video applications. Matching the impedance of the connector with that of the cable and system is crucial to minimize reflections and maintain optimal performance. Additionally, consider the connector's power rating and environmental resilience. Depending on your project’s demands, you may need connectors that can handle high power levels or those that are built to withstand harsh environmental conditions, including temperature fluctuations and exposure to moisture. Taking the time to evaluate these specifications will ensure that you select the right SMA male connector for your specific application.

Common Applications of SMA Male Connectors in Various Industries

SMA male connectors are essential components in numerous industries, particularly those involving telecommunications, aerospace, and medical equipment. These connectors ensure efficient signal transmission in systems ranging from RF applications to wireless communication. According to a report by MarketsandMarkets, the global RF connector market is projected to reach USD 4.14 billion by 2026, underscoring the rising importance of reliable connectivity solutions in integrated systems.

When selecting the right SMA male connector for your project, it's crucial to consider several factors. Firstly, the frequency range of your application must align with the specifications of the connector to avoid signal loss. For instance, SMA connectors are typically rated for frequencies up to 18 GHz, making them ideal for many high-frequency applications. Additionally, ensure that the connector's material can withstand environmental conditions, especially in industries like aerospace where connectors may be exposed to extreme temperatures and vibrations.

Incorporating tips while choosing an SMA male connector can further enhance your project's success. Prioritize connectors with a good mating durability as this can significantly extend your equipment’s lifespan. Moreover, ensure compatibility with existing components to avoid costly modifications. Finally, consider the ease of installation, as user-friendly designs can reduce setup time and minimize potential errors during implementation.

10 Essential Tips for Choosing the Right SMA Male Connector for Your Project - Common Applications of SMA Male Connectors in Various Industries

| Tip Number | Tip Description | Common Applications | Industry Use |

|---|---|---|---|

| 1 | Check the frequency range of the connector. | Radio Frequency (RF) communications | Telecommunications |

| 2 | Ensure the connector is compatible with the cable type. | Antenna connections | Aerospace |

| 3 | Consider the connector's durability and environmental rating. | Weather-resistant applications | Industrial |

| 4 | Evaluate the power handling capabilities. | High-power RF systems | Consumer electronics |

| 5 | Look for connectors with good VSWR characteristics. | Signal transmission optimization | Broadcasting |

| 6 | Assess the ease of installation and maintenance. | Routine equipment upgrades | Network infrastructure |

| 7 | Select a connector with suitable size and dimension. | Compact electronic devices | Mobile technology |

| 8 | Verify connector plating material for corrosion resistance. | Exposed outdoor installations | Infrastructure |

| 9 | Look into performance specifications for your application. | Precision measurement setups | Research and development |

| 10 | Ensure reliable vendor support and documentation available. | Complex integrated systems | Telecommunication |

Evaluating the Quality and Reliability of SMA Male Connectors

When selecting an SMA male connector for your project, evaluating the quality and reliability of the components is paramount. According to a report by the International Society of Automation, connectors can account for up to 25% of the total failure rate in RF systems. This statistic underscores the importance of meticulous selection. Key indicators of quality include materials used in construction, impedance consistency, and environmental resistance. For example, connectors made from brass with gold plating offer better conductivity and corrosion resistance compared to those made from lower-grade materials.

Another critical aspect is the performance specifications, such as frequency range and VSWR (Voltage Standing Wave Ratio). The American National Standards Institute (ANSI) recommends that a good SMA connector should maintain a VSWR of 1.15 or better from DC up to 18 GHz. Poor VSWR can lead to signal loss and degradation, further impacting the reliability of the overall system. Moreover, thermal and mechanical considerations are vital—connectors that can withstand extremes in temperature and mechanical stress contribute significantly to long-term reliability in demanding applications.

Investing in connectors that meet stringent quality standards is essential for ensuring your project's success and the integrity of its communication systems.

Tips for Sourcing SMA Male Connectors from Reputable Suppliers

When sourcing SMA male connectors, the quality and reliability of your supplier play a crucial role in the success of your project. A reputable supplier should have a history of providing high-quality products and excellent customer service. This helps ensure that the connectors meet your performance specifications and can withstand the demands of your application. Start by researching potential suppliers through industry forums, evaluations, and customer feedback.

One essential tip is to request samples before making a bulk purchase. This allows you to assess the quality and performance of the SMA connectors in real-world conditions. Additionally, inquire about the supplier's manufacturing processes and quality control measures to ensure they adhere to industry standards. Another key factor is the supplier's ability to provide technical support. Having access to knowledgeable representatives who can assist with installation or troubleshooting can be invaluable, especially for complex projects.

Lastly, consider the supplier's lead times and flexibility regarding order quantities. A reliable supplier should be able to meet your deadlines without compromising quality. Establishing a strong relationship with a trusted supplier can lead to better pricing, tailored solutions, and priority service, ultimately benefiting your project's overall success.

Related Posts

-

Understanding the Importance of SMA Male Connectors in Modern Technology Systems

-

How to Choose the Right SMA Male Connector for Your Project

-

What You Need to Know About SMA Male Connectors for Your Next Project

-

The Definitive Ultimate Guide to Mastering Wire Harness Assembly for Optimal Performance

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier

-

How to Select the Right Electrical Harness Connectors for Your Projects