How to Select the Right Electrical Harness Connectors for Your Projects

When embarking on a project that requires the integration of electrical systems, one of the most critical components to consider is the selection of

electrical harness connectors. These connectors not only ensure the stability and functionality of electrical connections but also play a pivotal role in the overall

efficiency and safety of the system. With a wide array of options available, choosing the right electrical harness connectors can be daunting. This introductory guide aims to illuminate the key factors that should be considered during the selection process, including the specific requirements of your project, environmental considerations, and compatibility with various wire types and gauges.

By understanding these elements, you can make informed decisions that will enhance the performance and reliability of your electrical systems.

Understanding the Role and Importance of Electrical Harness Connectors

Electrical harness connectors play a crucial role in the functionality and reliability of any electrical system. These connectors are essential for linking various components within an electrical harness, enabling the seamless transmission of power and signals. As systems become increasingly complex, the importance of selecting the right connectors cannot be overstated. The performance of electrical devices often hinges on the integrity of these connectors, making them a vital consideration in design and engineering processes.

Choosing the appropriate electrical harness connectors involves understanding several factors, including the environmental conditions in which they will operate, the electrical specifications such as voltage and current ratings, and the mechanical requirements pertaining to size and durability. For instance, connectors exposed to harsh weather conditions must be watertight and resistant to corrosion, while those used in high-temperature environments need to withstand elevated heat without compromising their integrity. Ultimately, investing time in selecting the right connectors enhances the overall performance and longevity of electrical systems, ensuring they operate efficiently and safely across various applications.

Identifying Your Project's Specific Connector Requirements

When selecting the appropriate electrical harness connectors for your projects, it's crucial to begin by identifying the specific requirements of your project. Consider factors such as the environmental conditions, electrical load, and connecting methods. For instance, projects like the Coomera Connector illustrate the importance of durability and reliability in connector choices, especially considering the extensive road infrastructure that may face harsh weather conditions. Ensuring that the connectors can withstand these challenges will lead to enhanced project longevity and performance.

Additionally, understanding the scope of your project is vital. Whether it's a large-scale initiative, like the $8.8 million Pea Ridge Connector, or a smaller connector project, the complexity of the electrical system will dictate the type of connectors needed. For example, high-speed connectivity may be required for projects involving significant data transfer, while simpler connectors may suffice for basic power applications. By clearly defining your project's connectors' specifications, you can ensure that you select the most effective solutions that align with your operational goals.

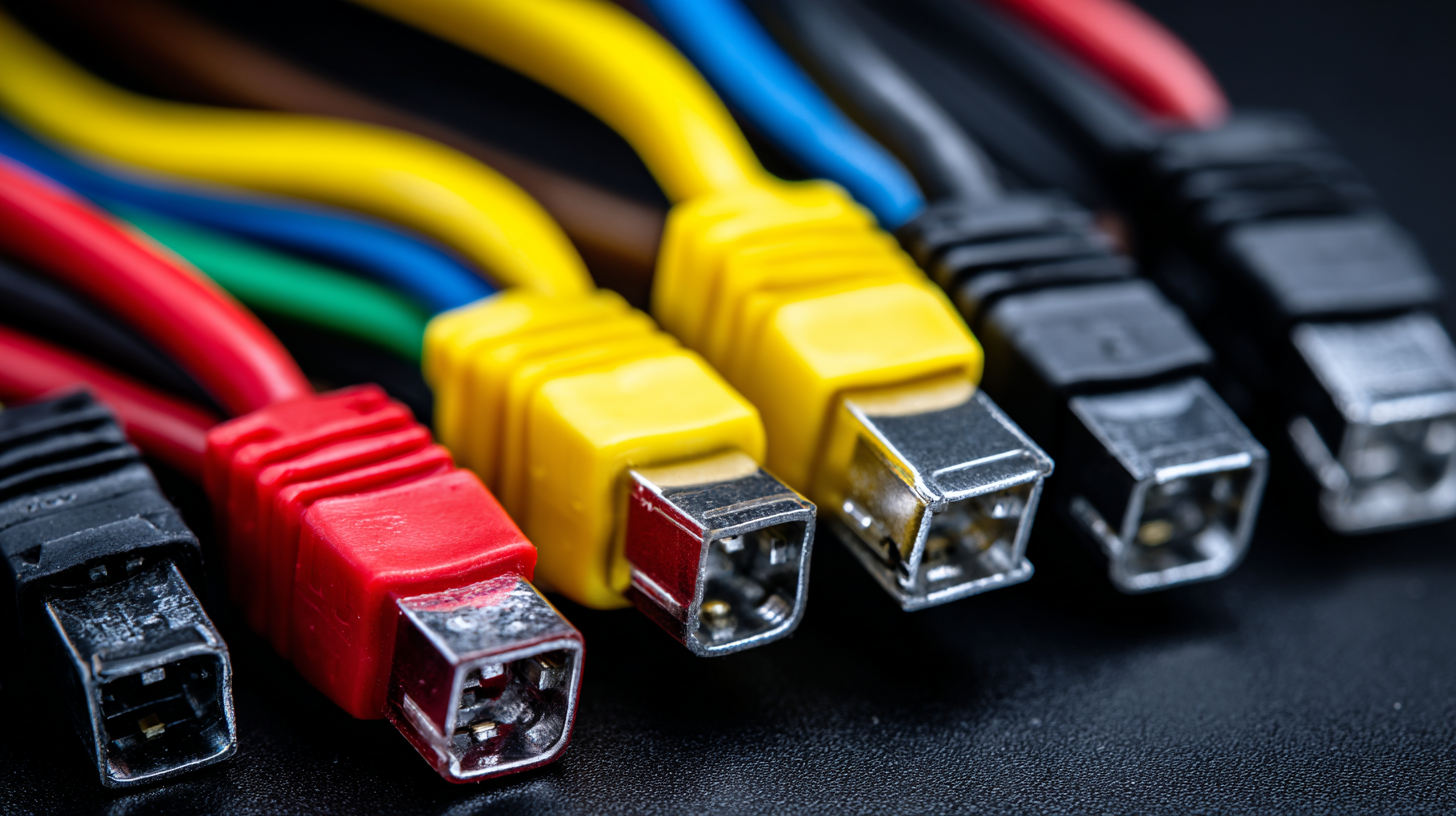

Exploring Different Types of Electrical Connectors and Their Applications

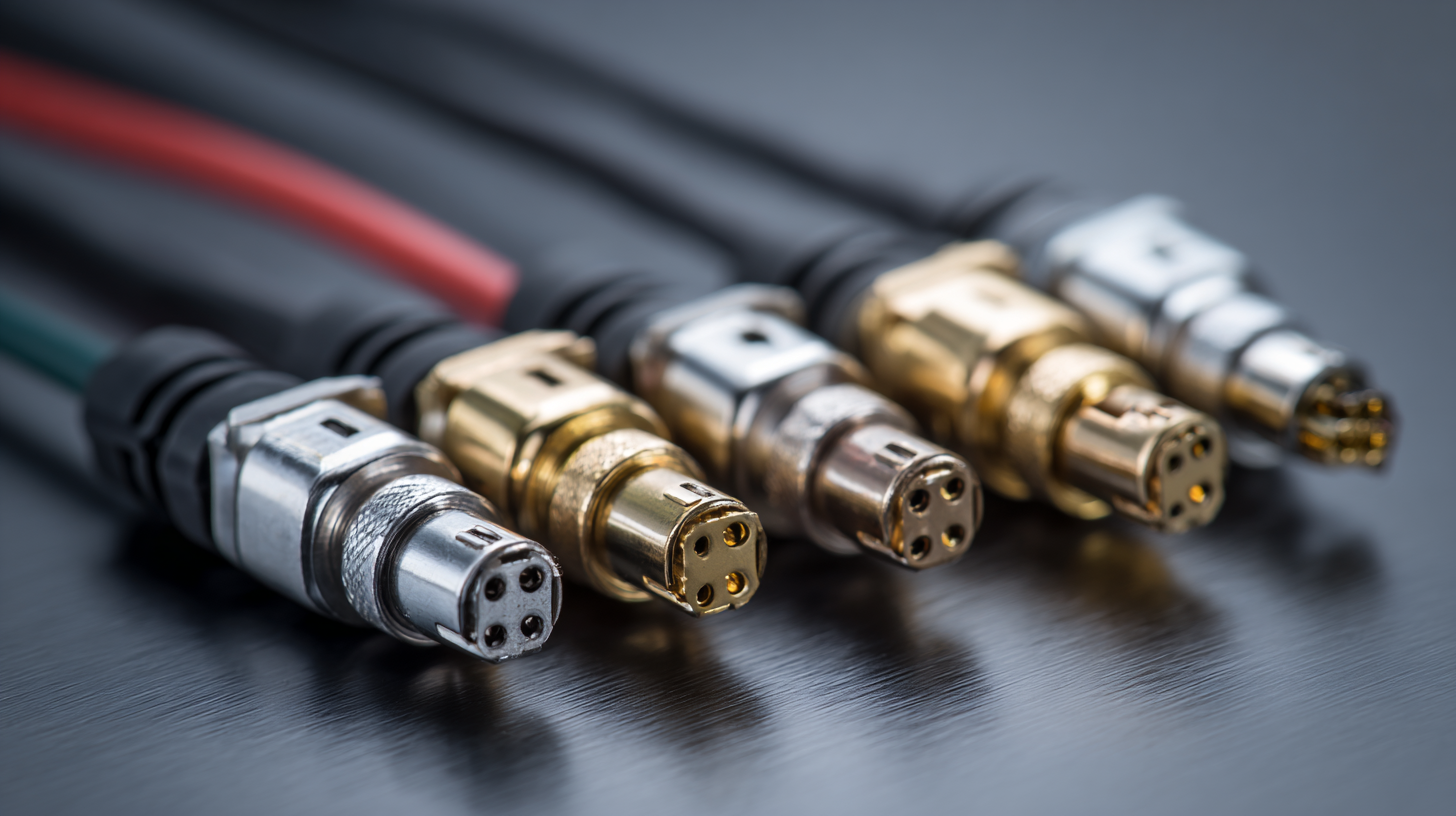

When selecting the right electrical harness connectors for your projects, understanding the different types available and their specific applications is crucial. Electrical connectors come in a variety of forms, including circular, rectangular, and modular connectors, each designed for specific types of environments and uses. For instance, circular connectors are often used in aerospace and military applications due to their robust design and resistance to environmental factors. Rectangular connectors, on the other hand, are commonly found in telecommunications and industrial machinery because they offer a higher pin count and ease of assembly.

Tips: When choosing connectors, always consider the environmental conditions they will face, such as humidity, temperature, and vibration. Additionally, assess the current and voltage requirements to ensure optimal performance and safety. Modular connectors can also provide flexibility in design, allowing you to customize the number of connections based on your project needs.

Moreover, it's essential to account for the layout and space constraints of your project. Compact connectors may be necessary for tight spaces, while larger connectors might be more suited for applications requiring high reliability and ease of maintenance. Identifying the right connector not only enhances performance but also contributes to the longevity of your electrical systems.

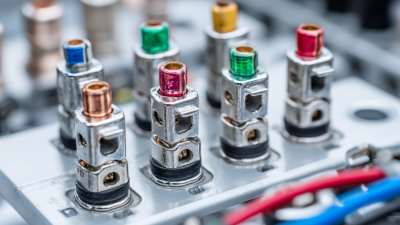

Evaluating Material and Environmental Factors for Connector Selection

When selecting electrical harness connectors for projects, a critical aspect is evaluating material and environmental factors that influence the connector's performance and longevity. The choice of materials primarily affects the connector's resistance to aging, their ability to withstand extreme temperatures, moisture, and corrosion, as well as their overall mechanical strength. An advanced aging law and life evaluation model can provide insights into the durability of cable insulation and connectors, ensuring reliability and effectiveness in various applications.

Moreover, the environmental conditions in which connectors will operate play a significant role in the selection process. Factors such as exposure to chemicals, UV radiation, and mechanical stresses must be considered. New methodologies like the WOA-SVR model allow for a more comprehensive analysis of how these environmental factors impact the life expectancy and reliability of insulating materials in harness connectors. By applying these evaluations, designers can make informed decisions, ensuring that the selected connectors not only meet the immediate performance criteria but also endure the test of time in diverse conditions.

Electrical Harness Connectors Material Selection

This chart illustrates the common applications of various materials used in electrical harness connectors. The materials selected vary based on environmental and application-specific requirements.

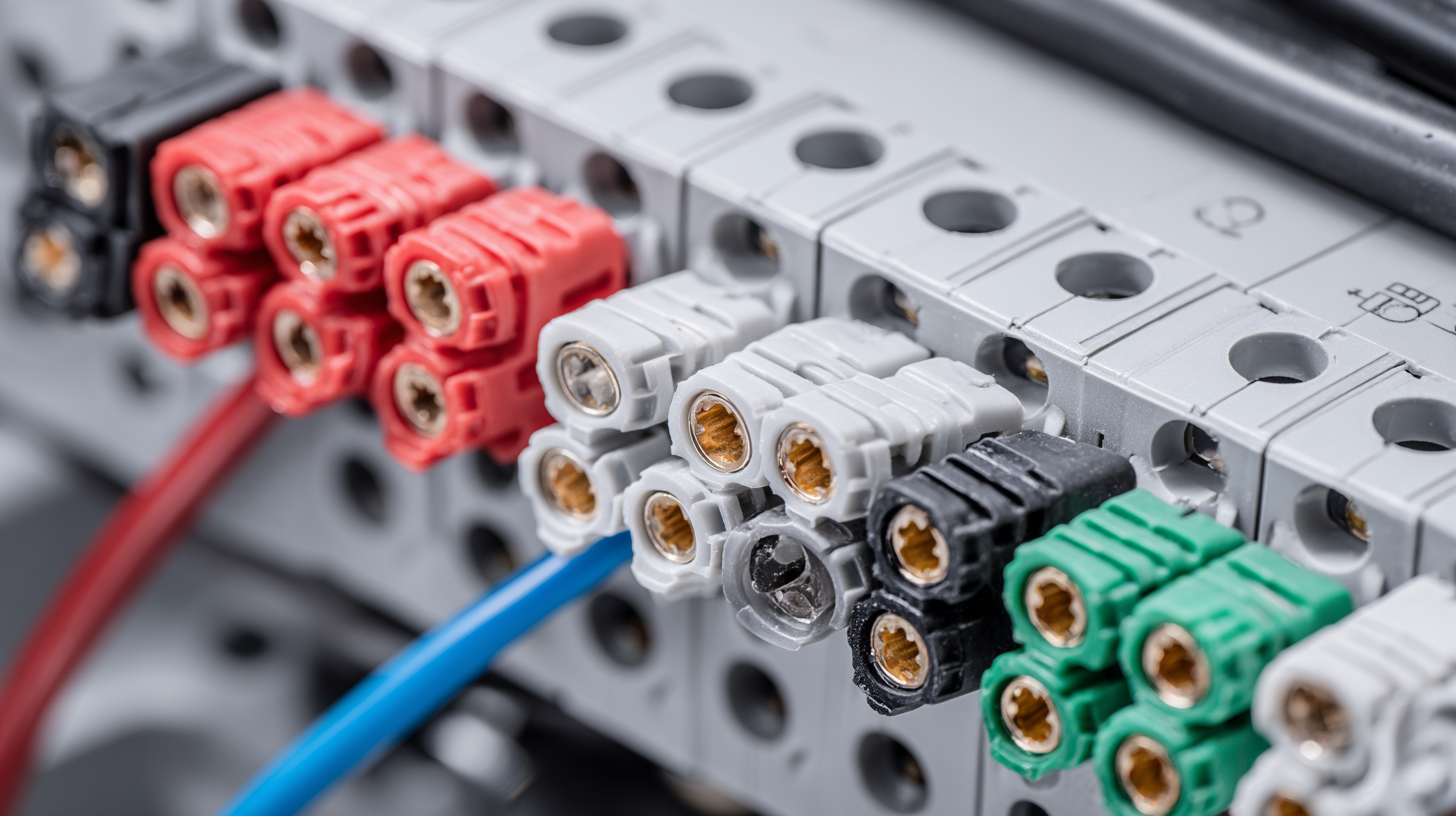

Best Practices for Sourcing and Installing Electrical Harness Connectors

When sourcing and installing electrical harness connectors, one must consider several best practices to ensure optimal performance and reliability. Firstly, understanding the specific requirements of the application is crucial. This includes assessing voltage, current ratings, and environmental conditions, which can help in selecting connectors that can withstand the operational stresses they will face. Additionally, the use of ferrules to enhance the connection characteristics of stranded wires can significantly improve the reliability of electrical connections, particularly in automotive and industrial applications.

In the integration of PCB-to-wire harness designs, electronic design automation (EDA) tools play a pivotal role. These tools streamline the design process, allowing for more efficient sourcing and installation of connectors. When dealing with complex systems, such as tractor-trailer electrical connections or rooftop photovoltaic setups, meticulous attention to the specifications and maintenance of connectors is vital. This proactive approach not only ensures the longevity of the electrical systems but also mitigates the risk of failures that could lead to costly repairs or downtime. Adhering to industry best practices is essential in achieving a successful installation and operational efficiency.

How to Select the Right Electrical Harness Connectors for Your Projects - Best Practices for Sourcing and Installing Electrical Harness Connectors

| Connector Type | Wire Gauge Compatibility | Temperature Rating (°C) | Moisture Protection | Applications |

|---|---|---|---|---|

| Crimp Connector | 22 - 10 AWG | -40 to 105 | IP67 | Automotive, Electrical Appliances |

| Sealed Connector | 20 - 14 AWG | -40 to 125 | IP68 | Marine, Outdoor Equipment |

| Multi-pin Connector | 24 - 20 AWG | -20 to 85 | N/A | Industrial Automation, Telecom |

| Stick-on Connector | 22 - 18 AWG | -30 to 90 | IP54 | Consumer Electronics, Small Devices |

Related Posts

-

Challenges Faced in Cable Harness Design Efficiency

-

How to Optimize Your Electrical Harness Assembly for Maximum Efficiency

-

How to Choose the Right Wire Terminals for Optimal Electrical Performance: Expert Insights and Data

-

The Ultimate Guide to Streamlining Your Harness Assembly Process for Maximum Efficiency

-

Innovative Applications of Molded Cable Assemblies Across Various Industries

-

What Is the Future of Wire Harness Manufacturing Equipment