2026 Top Electrical Harness Connectors to Consider?

As technology advances, the demand for reliable electrical harness connectors has grown significantly. These connectors are crucial in various applications, from automotive to aerospace sectors. In 2026, selecting the right electrical harness connectors is more important than ever. The wrong choice can lead to system failures and costly repairs.

Consider the impact of high temperatures and exposure to moisture on connector performance. Choosing a durable, high-quality connector can prevent future issues. Factors like size, weight, and ease of installation are also vital. What works well in one application may not be ideal for another.

Furthermore, understanding the evolving landscape of connector technology is essential. Innovations continue to emerge, making it challenging to stay current. Reflecting on past experiences with inferior connectors can guide future choices. In this environment, having a comprehensive list of top electrical harness connectors can provide invaluable insights for engineers and buyers alike.

Key Features to Look for in Electrical Harness Connectors

When choosing electrical harness connectors, certain key features are essential. Durability is at the forefront. Materials such as thermoplastics and metals are frequently used. They should withstand extreme temperatures. Reports indicate that connectors can fail at temperatures over 85 degrees Celsius. This can lead to system failures.

Another critical feature is the sealing capabilities. Connectors must protect against environmental factors like moisture, dust, and chemicals. According to recent statistics, nearly 30% of connector failures result from environmental exposure. A good connector should have an IP67 rating or higher. This ensures maximum protection and reliability in various conditions.

Furthermore, compatibility plays a crucial role. Connectors need to fit seamlessly within different systems. Issues arise if the connector does not match the wiring gauge or has differing terminal types. Inconsistent specifications often result in connection failures. A lack of standardized sizes complicates this. Selecting connectors with clear specifications and guidelines can greatly reduce these problems.

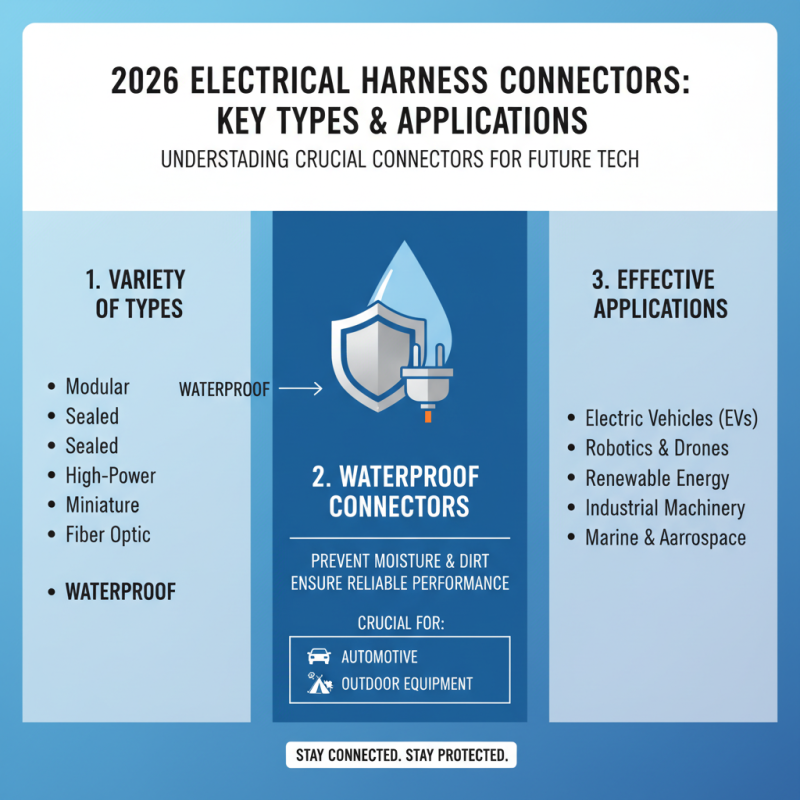

Types of Electrical Harness Connectors Available in 2026

The electrical harness connectors of 2026 will showcase a variety of types. Understanding these types is crucial for effective applications. One key type is the waterproof connector. These connectors prevent moisture and dirt from compromising electrical performance. They are vital in automotive and outdoor equipment.

Another notable type is the high-current connector. These connectors manage larger electrical loads. They are often used in industrial settings, where power demands are high. Compact designs with robust insulation are also emerging. These designs save space while ensuring durability and safety.

However, challenges remain. The rapid advancements can lead to compatibility issues with older systems. Users may struggle to find suitable connectors. Additionally, as new materials are introduced, testing for reliability becomes essential. Each of these concerns requires careful consideration in the design and selection process.

Top Brands and Manufacturers of Electrical Harness Connectors

In the world of electrical harness connectors, the choice of materials and reliability is crucial. Manufacturers are constantly innovating to meet industry demands. Data shows that the global electrical connectors market is expected to grow by over 5% annually, driven by the increasing need for better connectivity in various sectors like automotive and aerospace.

Popular materials include plastic and metal, each with distinct advantages. Plastics are lightweight and resistant to corrosion, while metals provide strength and durability. The right choice depends on application specifics. For instance, automotive applications often require connectors with high-temperature resistance.

**Tip:** Always consider the operating environment before selecting connectors. While many connectors may seem suitable, their performance can vary under different conditions.

When evaluating brands, look for those with a proven track record in quality. Factors such as certification and customer feedback play a vital role. Not all brands guarantee long-term performance. Some may fail under stress, leading to costly downtimes.

**Tip:** Don't just rely on brand reputation. Conduct thorough research and testing to ensure connectors meet your project's requirements. Selecting the wrong connector can lead to significant setbacks.

Applications of Electrical Harness Connectors Across Industries

Electrical harness connectors play a vital role across various industries. In automotive manufacturing, they ensure a reliable connection for power and data transmission. The connectors must withstand vibrations, moisture, and temperature shifts. A single failed connector can lead to costly recalls or repairs.

In aerospace, the stakes are higher. These connectors are used in critical systems. They must pass rigorous testing for safety and performance. Even a tiny flaw can jeopardize a flight. Engineers often face challenges selecting the right connector type for specific applications.

In renewable energy, connectors facilitate solar and wind systems. They connect panels and turbines to inverters and batteries. The harsh outdoor conditions pose risks to performance. Regular maintenance is vital, but can be overlooked. Choosing durable connectors can enhance longevity, but it’s an ongoing challenge. Each industry has unique needs, highlighting the complexity of connector selection.

2026 Top Electrical Harness Connectors by Industry Application

Future Trends in Electrical Harness Connector Technology

The future of electrical harness connector technology is rapidly evolving. Industry reports suggest that the global market for these connectors is projected to reach $18.3 billion by 2026. This growth is largely driven by advancements in automation and electric vehicles. Manufacturers are increasingly focused on minimizing space and weight in designs. Lighter connectors can improve fuel efficiency and increase performance.

One prominent trend is the shift toward smart connectors. These devices incorporate sensors to monitor performance in real-time. According to a report by a leading analytics firm, smart connectors could reduce maintenance costs by 25%. However, the technology is still developing, and issues related to compatibility remain a challenge. Not all systems communicate effectively, leading to potential failures in critical applications.

Another aspect under observation is sustainability. As industries focus on environmental responsibility, eco-friendly materials are gaining traction. Yet, the transition to greener materials isn’t straightforward. Performance under extreme conditions is often a concern. Ensuring reliability while meeting sustainability goals requires thoughtful innovation. The balance between eco-friendliness and performance is a complex issue needing further exploration.

2026 Top Electrical Harness Connectors to Consider

| Connector Type | Material | Temperature Rating (°C) | Max Current (Amperes) | Key Features |

|---|---|---|---|---|

| Sealed Connectors | Thermoplastic | -40 to 125 | 20 | Water-resistant, compact design |

| High-Voltage Connectors | Metal Alloy | -20 to 150 | 100 | High dielectric strength, durability |

| Modular Connectors | Polyamide | -30 to 85 | 15 | Customizable, ease of assembly |

| Automotive Connectors | Polycarbonate | -40 to 125 | 30 | Vibration-resistant, lightweight |

| RF Connectors | Brass | -40 to 199 | 5 | High-frequency applications, low loss |

Related Posts

-

The Definitive Ultimate Guide to Mastering Wire Harness Assembly for Optimal Performance

-

The Ultimate Guide to Streamlining Your Harness Assembly Process for Maximum Efficiency

-

What is a Cable Wire Harness and How Does It Power Modern Innovations?

-

How to Optimize Your Electrical Harness Assembly for Maximum Efficiency

-

Revolutionizing Your Production: The Future of Wire Harness Design and Its Impact on Manufacturing Efficiency

-

Top Uses and Applications of SMA Female Connector in Wireless Technology