Top 10 Reasons to Choose the Right Harness Cable Assembly for Your Project

In the ever-evolving world of technology, the importance of selecting the right harness cable assembly for any project cannot be overstated. Renowned industry expert Dr. Emily Carter, a leading specialist in cable design and manufacturing, emphasizes this necessity by stating, “The success of any electrical project relies heavily on the quality and suitability of its harness cable assembly.” This highlights how critical it is to make informed decisions when it comes to harness cable assemblies, as they play a vital role in ensuring optimal performance and reliability.

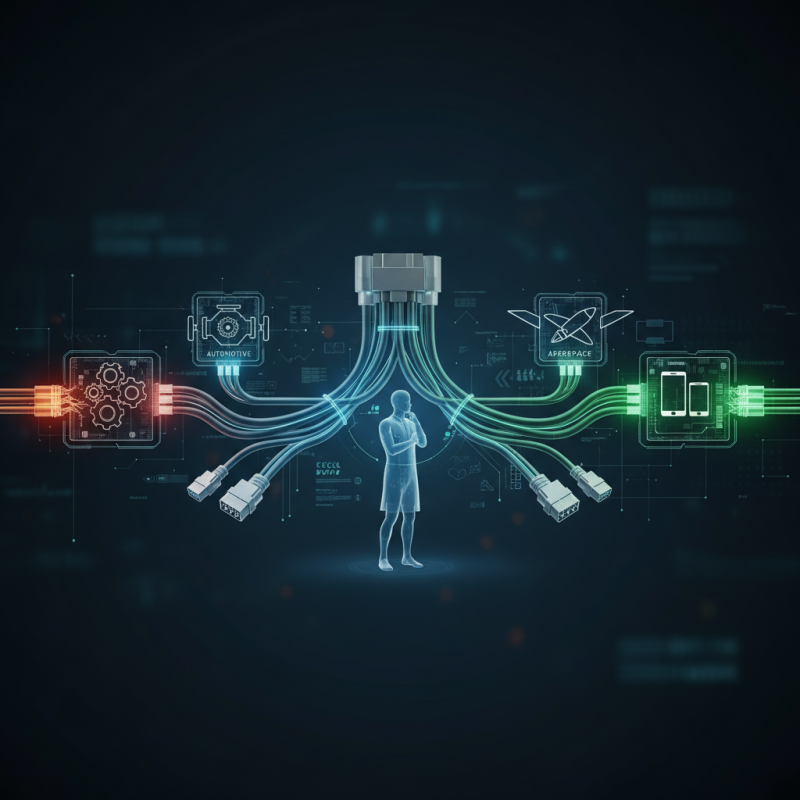

Choosing the appropriate harness cable assembly can significantly impact the overall functioning of a system, whether for automotive, aerospace, or consumer electronics applications. With the right assembly, projects can benefit from enhanced durability, improved signal integrity, and reduced maintenance costs. Conversely, a poor choice can lead to failures that undermine project success and increase long-term expenses. Through careful consideration and understanding of the various factors at play, project managers and engineers can avoid common pitfalls and set their initiatives on a path to success. As we delve into the top reasons for selecting the right harness cable assembly, it becomes clear that informed choices lead to innovation and efficiency in every endeavor.

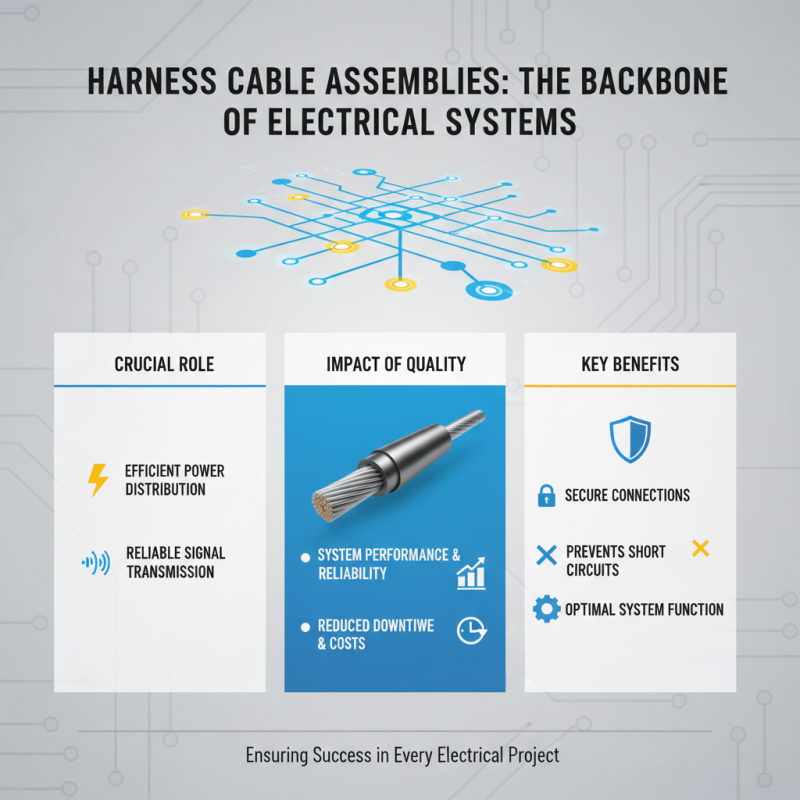

Importance of Harness Cable Assembly in Electrical Projects

Harness cable assemblies play a crucial role in the success of electrical projects. They serve as the backbone of electrical systems, providing efficient power distribution and signal transmission across various components. The design and quality of these assemblies can significantly influence the performance and reliability of the entire system. A well-designed harness cable assembly ensures that electrical connections are secure, reducing the risk of short circuits, signal loss, and potential system failures, which can lead to costly downtime.

Moreover, choosing the right harness cable assembly is essential for enhancing the safety and longevity of electrical projects. High-quality materials and proper insulation are vital to protect against environmental factors such as moisture, temperature fluctuations, and mechanical stress. This not only helps in maintaining the integrity of the electrical system but also contributes to the overall safety of the project, minimizing potential hazards for both users and equipment. By prioritizing the importance of harness cable assemblies, engineers and project managers can ensure that their electrical systems are robust, reliable, and ready to meet the demands of modern technology.

Key Specifications to Consider in Harness Cable Assembly Selection

When selecting a harness cable assembly for your project, it is vital to consider several key specifications to ensure optimal performance and reliability. The first major consideration is the gauge of the wire used in the assembly. Wire gauge affects the current-carrying capacity; for example, according to the American Wire Gauge (AWG) standards, thicker wires (lower gauge numbers) can handle more current, thus supporting higher power applications. A thorough analysis of the power requirements of the intended application is crucial, as employing a wire that is too thin can lead to overheating and potential failure.

Another critical specification is the insulation type and material of the cables. Different projects may require unique insulation properties based on environmental factors such as temperature, moisture, and exposure to chemicals. For instance, a report from the Institute of Electrical and Electronics Engineers (IEEE) highlights that thermoplastic insulation offers superior flexibility and resistance in a range of temperatures, making it ideal for automotive applications. Furthermore, connectors within a harness must also be scrutinized for compatibility with the assembly’s intended use, with options ranging from sealed connectors for harsh environments to high-speed connectors for data transmission.

Lastly, understanding the total length and routing of the cables is essential for minimizing signal loss and maintaining overall system integrity. Per industry standards, longer cable runs necessitate careful attention to impedance and capacitance characteristics to avoid degraded performance, particularly in high-frequency applications. Ultimately, by paying meticulous attention to these specifications, you can ensure that your harness cable assembly meets both functional requirements and industry performance standards.

Top 10 Reasons to Choose the Right Harness Cable Assembly for Your Project

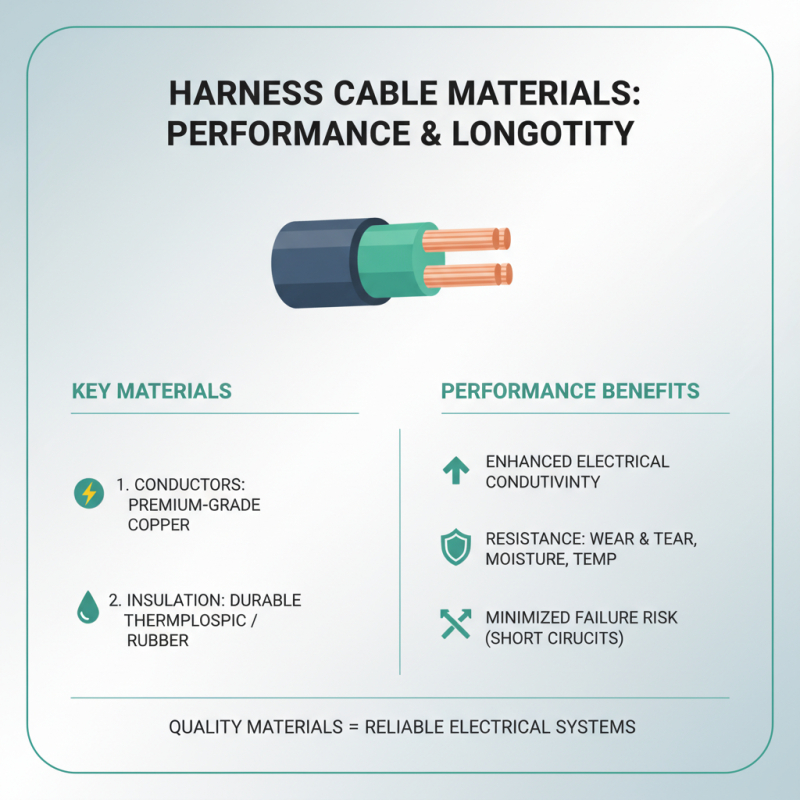

Impact of Quality Materials on Harness Cable Performance and Longevity

The choice of materials in harness cable assemblies significantly impacts their performance and longevity. High-quality materials such as premium-grade copper for conductors and durable thermoplastic or rubber for insulation ensure that the cables can withstand various environmental factors. These materials not only enhance the electrical conductivity but also provide resistance against wear and tear, moisture, and temperature fluctuations. When the right materials are selected, the risk of failure due to short circuits or insulation breakdown is minimized, which is crucial for maintaining the integrity of any electrical system.

Furthermore, the longevity of harness cable assemblies is directly linked to the robustness of the materials used. Assemblies made with subpar materials often suffer from premature aging, leading to frequent replacements and increased maintenance costs. On the other hand, cables built with high-quality components exhibit exceptional durability, allowing them to perform optimally over extended periods. This reliability is particularly vital in industrial applications, where consistent performance can directly affect operational efficiency and safety. By prioritizing quality materials in harness cable assembly, projects can achieve enhanced performance and longevity, ultimately contributing to the success of their electrical systems.

Cost-Benefit Analysis: Choosing the Right Harness Cable for Your Budget

When embarking on a project that requires a cable assembly, conducting a cost-benefit analysis is paramount to ensure that your budget aligns with your operational needs. According to a report by MarketsandMarkets, the global harness cable assembly market is projected to grow from $42.96 billion in 2021 to $61.02 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.4%. This growth highlights the importance of not just choosing a high-quality harness, but also one that is cost-effective. Opting for the right harness cable assembly can mitigate long-term expenses associated with maintenance, repairs, and replacements, which are crucial factors in any project budget.

In the realm of harness cable assemblies, the selection process involves weighing the initial costs against potential savings over time. A well-designed assembly can enhance product reliability and efficiency, reducing downtime and maintenance costs. Industry reports indicate that businesses can save anywhere from 15% to 30% on operational costs simply by investing in the right harness solutions upfront. Furthermore, the increased durability offered by higher-quality materials often results in longer lifespans for the assemblies, thereby minimizing the need for replacements and contributing to a healthier bottom line. By prioritizing a thorough cost-benefit analysis before making a purchase, project managers can avoid overspending while ensuring their projects run smoothly.

Industry Standards and Certifications for Reliable Harness Cable Assemblies

When selecting harness cable assemblies for your project, adherence to industry standards and certifications is crucial for ensuring reliability and performance. Various organizations, such as the Society of Automotive Engineers (SAE) and the International Electrotechnical Commission (IEC), set forth guidelines that dictate the quality requirements for cable assemblies. For instance, wiring harnesses used in automotive applications must comply with the SAE J2030 standard, which emphasizes the importance of durability and electrical performance under varying environmental conditions. According to a recent report by the International Wire and Cable Manufacturers Association (IWCM), nearly 30% of cable assembly failures can be traced back to non-compliance with established standards.

Tips: When designing your harness cable assembly, always verify that materials and processes meet relevant industry standards. This not only enhances the reliability of your product but can also mitigate future costs associated with recalls or replacements due to failures.

In addition to following industry standards, it's essential to choose components that have been certified by recognized testing organizations, such as Underwriters Laboratories (UL) or the American National Standards Institute (ANSI). These certifications guarantee that the materials can withstand the specific demands of your application, from extreme temperatures to high electrical loads. A recent survey indicated that products with recognized certifications saw a 40% reduction in failure rates compared to untested alternatives, highlighting the importance of thorough selection processes in harness assembly projects.

Tips: Keep documentation of certifications for all components as this will not only streamline the approval process but also reassure stakeholders regarding the safety and reliability of your project.

Related Posts

-

What is a Cable Harness? Exploring Its Role in Modern Connectivity and Industry Applications

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier

-

Exploring Cable and Harness Assembly Innovations at the 138th China Import and Export Fair 2025

-

Challenges Faced in Cable Harness Design Efficiency

-

Innovative Applications of Molded Cable Assemblies Across Various Industries

-

The Ultimate Guide to Streamlining Your Harness Assembly Process for Maximum Efficiency