Top 10 Tips for Effective Harness Assembly Techniques?

Harness assembly plays a crucial role in many industries. Experts emphasize the importance of mastering this skill. John Smith, a leading authority in the field, states, "Precision in harness assembly can make or break a project."

The effectiveness of harness assembly hinges on attention to detail. Each component has a specific role, and any small error can lead to significant issues. For instance, improper connections may result in safety hazards or equipment failures.

Reflecting on past experiences, some may find that their harness assembly techniques were rushed or poorly executed. This can lead to frustration during assembly and testing phases. Each error presents an opportunity for improvement, reinforcing the need to revisit and refine one's approach. Success is found in the commitment to perfecting these essential techniques.

Effective Harness Assembly Techniques: An Overview of Best Practices

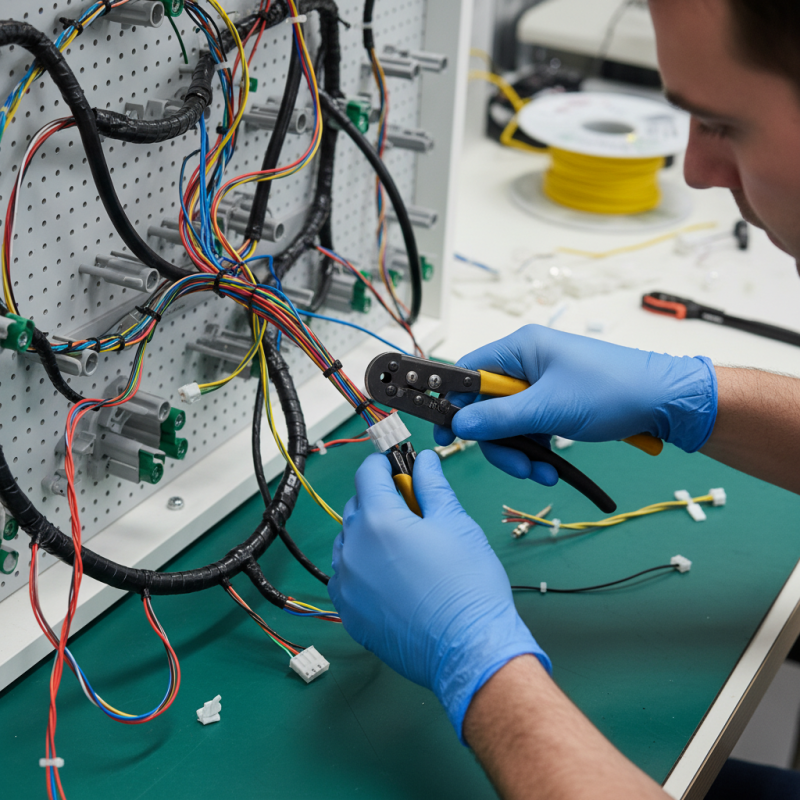

Effective harness assembly requires careful attention to detail. Start by organizing all components clearly. Gather wires, connectors, and tools in one location. This helps avoid confusion and mistakes during assembly. Even a small oversight can lead to significant issues later.

Use color-coded wires for easier identification. This simple step can reduce errors. Each color should represent a specific function. However, mistakes can happen if labels are missed or misread. It’s important to double-check your work. Don’t rush; impatience can lead to improperly assembled harnesses.

Test the harness functionality after assembly. Use a multimeter to ensure proper connections. Confirm that each wire delivers the expected signal or power. If you find any issues, revisit the assembly process. Reflecting on what went wrong is essential for improvement. Quality assembly is a continual learning experience. Enjoy the process and strive for better results each time.

Understanding the Importance of Proper Material Selection in Harness Assembly

When assembling harnesses, the choice of materials is crucial. Proper material selection impacts durability and performance. A report from the Harness Manufacturing Association states that over 30% of harness failures stem from inadequate materials. Selecting the right wires, insulation, and connectors can prevent many technical issues.

High-quality materials can withstand temperature fluctuations. They resist wear and corrosion better than lower-grade options. For instance, using quality thermoplastic elastomers instead of standard PVC can significantly improve longevity. Some manufacturers overlook this detail. This might lead to serious operational failures down the line.

Additionally, compatibility between components is vital. Using mismatched materials can result in bonding problems. Reports indicate that up to 20% of assembly time is wasted due to these mismatches. Regular reviews and tests can help identify potential issues early. Not all teams prioritize this, which can lead to regrets once a harness is deployed in the field. Proper planning and material analysis are necessary for effective harness assembly.

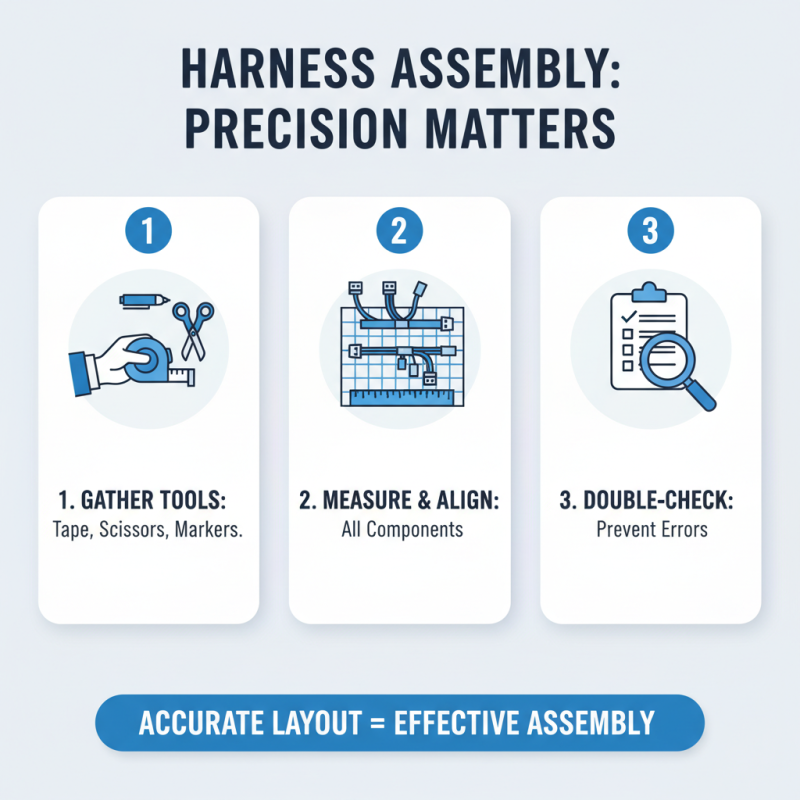

Step-by-Step Guide to Accurate Harness Measurement and Layout Techniques

Measuring and laying out harnesses accurately is crucial for effective assembly. Start with gathering the right tools. A flexible measuring tape, scissors, and markers are essential. Take precise measurements of all components. Ensure everything is aligned and arranged properly. It’s easy to misplace a few centimeters here and there. This can lead to issues down the line, so double-check each measurement.

When laying out the harness, visualize the final product. Sketching a layout can help organize the components. Use a flat surface and make sure all parts are accessible. Small mistakes can cause larger problems later. Mark key positions clearly. Do not rush through this step; it might seem tedious, but it’s vital. If you find errors, adjust before moving on. Taking a moment to reflect can save you time in the long run.

Remember, accuracy is a skill developed over time. Don’t get discouraged by initial mistakes. Each assembly session is a learning experience. Pay attention to the details, and you’ll improve with practice. Keep refining your techniques and maintain an open mindset. Adjusting your approach is not a failure; it’s a pathway to mastery.

Common Assembly Errors and How to Avoid Them During Harness Construction

When assembling a harness, many common errors can arise. One of the most frequent mistakes is improper alignment of wires. Misaligned wires may lead to shorts or failed connections. It’s crucial to double-check the layout before securing anything.

Another typical error is inadequate stripping of wire insulation. Too much or too little can compromise the integrity of the connection. A clear, clean strip of around 1/4 inch is ideal in most cases. Keeping tools like wire strippers in good condition helps prevent these mistakes.

Many overlook the importance of correct soldering techniques. Insufficient heat can result in weak joints. Alternatively, too much heat may damage the components. Practice and patience are key. Experience reflects in these seemingly small details. Proper training and reflection on past mistakes can drastically improve assembly quality.

Top 10 Tips for Effective Harness Assembly Techniques

Utilizing Industry Standards and Guidelines for Quality Assurance in Assemblies

When it comes to harness assembly, adhering to industry standards is crucial. Organizations like the Aerospace Industry Association report that non-compliance can lead to increased costs by up to 25%. Utilizing established guidelines ensures that assemblies meet essential quality requirements. It is vital to keep detailed records throughout the assembly process. Traceability is key for evaluations.

Proper training for assembly personnel can improve assembly quality substantially. A recent study found that trained staff can reduce errors by 40%. Not focusing on ongoing training can lead to recurring mistakes. It’s important to cultivate an environment that values continuous improvement. Regular feedback loops can identify issues early and prevent larger problems later.

Quality assurance requires collaboration among all team members. Open communication helps in addressing flaws swiftly. Ignoring communication can leave gaps that lead to assembly defects. Adopting a team-oriented approach fosters accountability. Ultimately, industry standards and proactive techniques play a significant role in enhancing assembly quality and efficiency.

Top 10 Tips for Effective Harness Assembly Techniques

| Tip Number | Tip Description | Industry Standard | Quality Assurance Method |

|---|---|---|---|

| 1 | Use high-quality materials for durability | ISO 9001 | Material Quality Testing |

| 2 | Follow the correct wiring schematic | IPC/WHMA-A-620 | Visual Inspection |

| 3 | Ensure proper strain relief for connectors | UL 486A | Functionality Testing |

| 4 | Implement consistent soldering techniques | J-STD-001 | Solder Joint Inspection |

| 5 | Maintain a clean working environment | EIA-625 | Environmental Monitoring |

| 6 | Use appropriate connector types for applications | IEC 61076 | Connector Compatibility Testing |

| 7 | Perform regular training for assembly personnel | ANSI/ASQ Z1.4 | Skill Assessment |

| 8 | Inspect each harness assembly before final testing | IPC-A-610 | Pre-Delivery Inspection |

| 9 | Document all assembly processes and exceptions | ISO 13485 | Traceability Audits |

| 10 | Continuously review and improve assembly techniques | Lean Manufacturing Standards | Process Improvement Reviews |

Related Posts

-

Essential Harness Assembly Checklist for Streamlined Production Efficiency

-

Top Trends in Harness Assembly Techniques for 2025 You Need to Know

-

Understanding the Role of Electrical Harness Connectors in Modern Technology: A Comprehensive Guide

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier

-

2025 Top Trends in Wire Cable Assembly: Essential Insights for Industry Professionals

-

Innovative Applications of Molded Cable Assemblies Across Various Industries