Top Trends in Harness Assembly Techniques for 2025 You Need to Know

As we look towards 2025, the harness assembly industry is on the cusp of transformative changes that are set to reshape its practices and standards. Industry expert Dr. Emily Carter, a leading figure in the field of electrical engineering, emphasizes the importance of innovation in harness assembly techniques, stating, "Embracing new technologies is not just an option; it's a necessity for the future of harness assembly." This statement encapsulates the urgent call for evolution in how we approach the design and production of wire harnesses.

The landscape of harness assembly is rapidly evolving, driven by advancements in automation, sustainable materials, and integrated digital solutions. With the increasing demand for both efficiency and sustainability, companies are being pushed to reconsider their methods and invest in new technologies that enhance productivity, reduce waste, and improve overall quality. Techniques that were once standard are being supplemented, and in some cases replaced, by cutting-edge approaches that promise to enhance the assembly process.

In this introductory overview, we will delve into the top trends expected to shape harness assembly techniques by 2025. By examining these developments, from the rise of smart manufacturing to the integration of artificial intelligence, we aim to provide insights into how industry players can adapt and thrive in an increasingly competitive market. As we navigate these changes, the call for a renewed focus on innovation in harness assembly becomes ever more pertinent, heralding a future of exciting possibilities.

Emerging Materials in Harness Assembly for Enhanced Performance

The evolution of harness assembly techniques is increasingly influenced by the integration of emerging materials designed to enhance performance. In 2025, the focus will shift toward lighter, more durable materials that not only improve the efficiency of harness assemblies but also contribute to overall system performance. Advanced composites, such as carbon fibers and high-performance polymers, are being adopted for their superior strength-to-weight ratios, making them ideal for aerospace and automotive applications. These materials allow for the reduction of weight in harness assemblies while maintaining structural integrity, essential for modern engineering solutions.

In addition to lightweight materials, the adoption of sustainable options is gaining momentum in harness assembly. Biodegradable plastics and recycled composites are being explored to minimize environmental impacts while delivering high performance. As industries face increasing pressure to adopt sustainable practices, harness assemblies made from eco-friendly materials will cater to both regulatory demands and market preferences. Furthermore, the use of smart materials that can adapt to varying environmental conditions promises to revolutionize harness assembly techniques, offering enhanced functionality and reliability in diverse operating environments. These innovations herald a new era in harness assembly, emphasizing the importance of material choice in meeting performance and sustainability goals.

Top Trends in Harness Assembly Techniques for 2025 You Need to Know

| Technique | Key Features | Emerging Materials | Performance Benefits |

|---|---|---|---|

| Automated Wire Processing | Increased precision & reduced labor costs | Copper-plated aluminum | Weight reduction & enhanced conductivity |

| 3D Printing | Customizable designs & rapid prototyping | Thermoplastics | Complex geometries & reduced weight |

| Flexible Circuit Technology | Space-saving & lightweight design | Polyimide base materials | Improved reliability & performance |

| Modular Assembly Techniques | Easier assembly & maintenance | Composite materials | Enhanced durability & crash resistance |

| Smart Harness Technologies | Integration of sensors & data analytics | Conductive fabrics | Improved diagnostics & real-time monitoring |

Automation and Robotics: Revolutionizing the Harness Assembly Process

The integration of automation and robotics into harness assembly techniques is poised to transform the industry significantly by 2025. These advancements streamline processes, improve precision, and enhance overall efficiency. Utilizing robotic systems for repetitive tasks, such as wire cutting and component placement, reduces human error and speeds up production times. Automation systems can also monitor performance and adapt to real-time demands, ensuring a more flexible manufacturing environment that can respond to varying orders without sacrificing quality.

In addition to improving productivity, automation and robotics bring about greater safety in harness assembly processes. Robots can handle heavy lifting and hazardous materials, allowing human workers to focus on more complex and oversight roles. This shift not only maintains safety standards but also helps to mitigate worker fatigue.

By implementing advanced machine learning algorithms, these systems can continuously learn from each operational cycle, leading to further improvements in process optimization and resource allocation. As we approach 2025, adopting these technologies will be essential for companies aiming to stay competitive and innovative in the ever-evolving landscape of harness assembly.

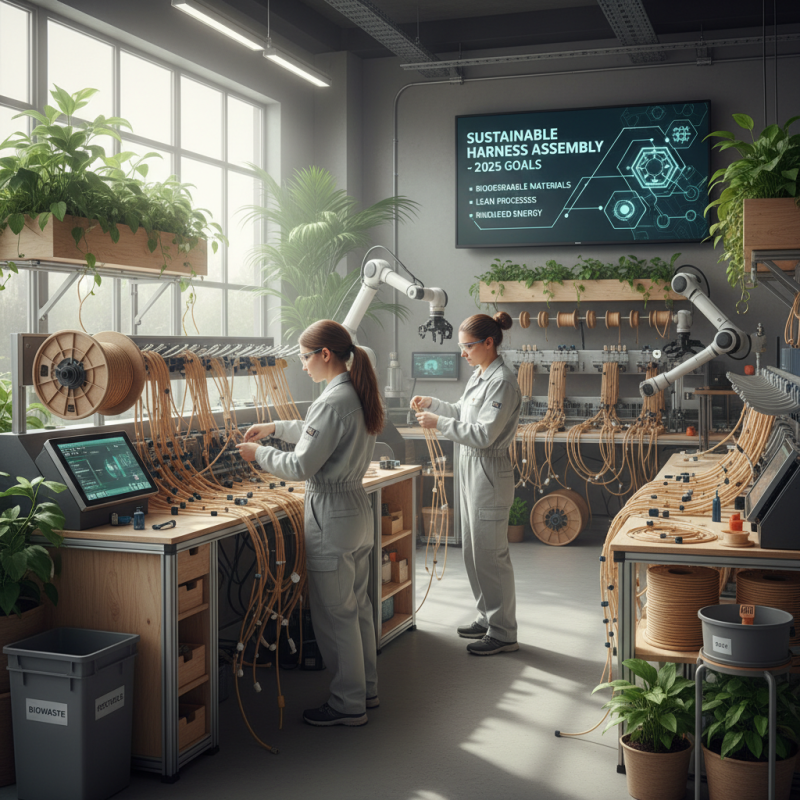

Sustainability Practices in Harness Assembly Techniques for 2025

As we move towards 2025, sustainability in harness assembly techniques is becoming an imperative in the industry. With increasing awareness of environmental impacts, companies are seeking methods that minimize waste and promote efficient resource usage. One key focus is the shift towards biodegradable materials in harness production, which not only reduces landfill contributions but also aligns with consumer expectations for eco-friendly products. Additionally, manufacturers are adopting lean assembly processes that streamline operations, leading to less energy consumption and decreased material waste.

Tips for incorporating sustainability practices into your harness assembly include evaluating your supply chain for sustainable material options and implementing energy-efficient machinery to reduce your carbon footprint. Furthermore, companies can engage employees in sustainability initiatives, fostering a culture of environmental responsibility that can generate innovative ideas for process improvements.

Another trend is the use of digital tools and technology to enhance transparency in the production process. By leveraging data analytics and IoT devices, companies can track resource usage, identify inefficiencies, and optimize operations. This not only contributes to sustainability efforts but also drives cost-effective solutions, ensuring a competitive edge in the market. Embracing these practices will not only benefit the environment but also position businesses favorably in the changing marketplace of 2025.

The Role of Digital Tools and Software in Harness Assembly Efficiency

As we look ahead to 2025, the landscape of harness assembly techniques is evolving, driven significantly by the integration of digital tools and software. A recent industry report indicates that companies adopting advanced digital solutions for harness assembly have observed a marked increase in efficiency, with productivity improvements of up to 30%. This shift towards digitalization not only streamlines the assembly process but also enhances accuracy, thereby minimizing errors during production.

The incorporation of software tools enables real-time monitoring and data analytics, which are crucial for optimizing harness assembly lines. For instance, digital twin technology allows manufacturers to create virtual replicas of their assembly processes, facilitating scenario testing and better resource allocation. According to a market analysis, the use of digital tools in manufacturing is expected to grow at a compound annual growth rate (CAGR) of 15% over the next few years, highlighting the growing recognition of these technologies' value. By embracing such innovations, companies can ensure that their harness assembly operations remain competitive and agile in an increasingly complex market.

Key Industry Innovations Shaping the Future of Harness Assembly

The harness assembly industry is poised for significant innovation in 2025, driven by advancements in technology and a growing demand for efficiency. A recent report from the Industrial Automation Society predicts that the implementation of automation tools in harness assembly could reduce production time by up to 30%. This is primarily due to the integration of robotics and advanced software systems that streamline assembly processes, making them not only faster but also more reliable. As manufacturers adopt these technologies, expect to see a shift towards more automated assembly lines, which can significantly reduce human error and operational costs.

In addition to automation, modular assembly techniques are gaining traction. According to a survey by the Engineering Guild, over 60% of industry leaders believe modular designs will dominate harness assembly by 2025. This approach allows for flexible configurations and easier maintenance, benefiting companies that need to adapt quickly to changing market demands. By leveraging modularity, manufacturers can foster greater scalability and efficiency in their operations.

Tips:

- Embrace automation: Investing in automated systems can lead to enhanced productivity and precision in harness assembly.

- Consider modular designs: Implementing modular approaches can provide the flexibility to adapt to evolving technological challenges and customer needs.

Related Posts

-

Essential Harness Assembly Checklist for Streamlined Production Efficiency

-

The Definitive Ultimate Guide to Mastering Wire Harness Assembly for Optimal Performance

-

Understanding Electrical Wiring Harnesses: Key Trends and Industry Insights for 2024

-

5 Essential Reasons Your Business Needs a Reliable Cable Harness Supplier

-

What Is the Future of Wire Harness Manufacturing Equipment

-

Understanding the Role of Electrical Harness Connectors in Modern Technology: A Comprehensive Guide