Top Wire Assemblies Applications in Modern Technology?

In today's rapidly advancing technological landscape, wire assemblies play a crucial role in various applications. These assemblies are the backbone of electronic devices, automotive systems, and communication tools. According to a recent industry report by Research and Markets, the global wire assembly market is projected to reach $XX billion by 2025, reflecting a CAGR of 5.3%. This growth indicates the increasing reliance on wire assemblies in modern technology.

Expert insights shed light on this trend. "Wire assemblies are essential for ensuring signal integrity and overall performance in electronics," says John Smith, a leading figure in the wire assemblies industry. His perspective emphasizes the importance of quality and efficiency in manufacturing these components. However, the industry faces challenges such as material shortages and regulatory constraints. These obstacles highlight the need for continuous innovation and adaptation in wire assembly designs.

As technology evolves, the applications of wire assemblies are expanding beyond traditional sectors. Industries like renewable energy and medical technology increasingly depend on these components. Yet, there’s a gap in skilled labor to meet the growing demands. This situation calls for a reflection on workforce development to secure a robust future for the wire assemblies industry.

Overview of Wire Assemblies in Modern Technology

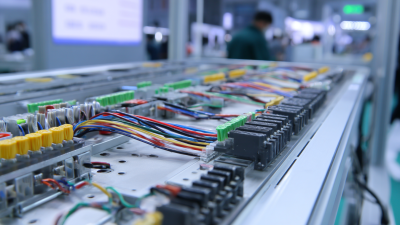

Wire assemblies play a crucial role in modern technology. They form the backbone of various applications, from consumer electronics to industrial machinery. According to a report by Markets and Markets, the wire harness market is projected to reach $86.3 billion by 2027, growing at a CAGR of 5.4%. This growth reflects the increasing demand for efficient and reliable electrical connections.

In the automotive sector, wire assemblies are particularly vital. They facilitate communication between sensors, control units, and actuators. A study by Grand View Research indicates that the automotive wire harness market alone is expected to reach $22.3 billion by 2025. However, challenges remain. The complexity of modern vehicles can lead to installation errors or faults, which are often overlooked during manufacturing.

Moreover, advancements in robotics and automation are spurring demand. Wire assemblies are essential for the functionality of robotic arms and automated systems. Yet, the varying quality of materials used poses risks. Not all suppliers maintain stringent quality control. This inconsistency can affect the reliability of wire assemblies, leading to potential failures in critical applications.

Key Materials Used in Wire Assemblies

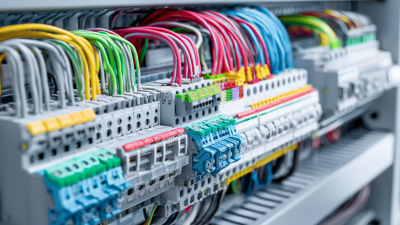

Wire assemblies play a crucial role in modern technology. They connect components in various devices. Common materials for these assemblies offer distinct advantages. Copper wire is a widely used choice. It provides excellent conductivity. This property ensures efficient energy transfer. However, it is prone to oxidation, which can affect performance.

Another key material is aluminum. It is lightweight and cost-effective. Aluminum wire assemblies are becoming more common in applications where weight is a priority. Yet, they can have lower conductivity than copper, a potential downside. Design engineers must consider these trade-offs carefully.

Insulation materials also matter in wire assemblies. PVC and polyurethane are popular options. PVC is durable and resistant to many chemicals. However, it can be less flexible. Polyurethane offers greater flexibility but may not endure harsh environments as well. Engineers face challenges in selecting the right combination of materials. Each choice influences performance, durability, and cost.

Top Wire Assemblies Applications in Modern Technology

| Application Area | Key Materials Used | Typical Use Cases |

|---|---|---|

| Consumer Electronics | Copper, Aluminum | Smartphones, Laptops, Tablets |

| Automotive | Copper, Silver-Plated Copper | Wiring Harnesses, Battery Cables |

| Telecommunications | Fiber Optics, Copper | Data Cables, Networking Equipment |

| Industrial Automation | Tinned Copper, PVC | Control Panels, Robotics |

| Medical Devices | Gold-Plated Copper, Silicone Insulation | Diagnostic Equipment, Surgical Tools |

| Aerospace | Aluminum, High-Temperature Alloys | Aircraft Wiring, Navigation Systems |

| Renewable Energy | Copper, PV Cable | Solar Panels, Wind Turbines |

Applications of Wire Assemblies in Consumer Electronics

In the world of consumer electronics, wire assemblies play a critical role. They serve as the backbone of devices such as smartphones, laptops, and wearables. Traditionally, these assemblies include connectors, terminals, and wires. Reports suggest that the global market for wire assemblies in consumer electronics is set to exceed $25 billion by 2025. This growth highlights the increasing complexity and integration of electronic components.

Quality wire assemblies ensure reliable connectivity. For example, a well-designed assembly can handle high currents, reducing the risk of overheating. However, challenges remain. Poor assembly practices can lead to connectivity issues, impacting device functionality. Inefficient wiring layouts can also complicate mass production and increase costs.

Moreover, the push for miniaturization affects wire assembly design. As devices become smaller, maintaining signal integrity becomes a struggle. The focus should shift to developing precision manufacturing techniques. It’s crucial to address these challenges to keep pace with the consumer electronics market’s rapid evolution.

Role of Wire Assemblies in Automotive and Aerospace Industries

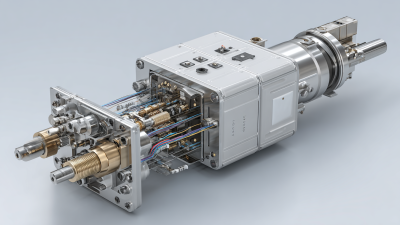

Wire assemblies play a critical role in modern automotive and aerospace industries. They ensure reliable electrical connections. According to a recent industry report, around 40% of vehicle failures relate to wiring harness issues. As vehicle designs become more complex, the demand for efficient wire assemblies increases. High-performance vehicles require lightweight and compact wiring solutions.

In the aerospace sector, the stakes are even higher. Aerospace wire assemblies must withstand extreme conditions, including high temperatures and vibrations. A study indicates that improper wire assembly can lead to a 25% increase in maintenance costs. Engineers are continually challenged to improve safety and reduce weight while maintaining functionality. This balance is essential but often difficult to achieve.

Moreover, the rise of electric vehicles adds further complexity. New technologies introduce varying requirements for wire assemblies. The shift towards automated manufacturing processes is promising but not without its flaws. Quality control often suffers due to rapid production speeds. This encourages continual assessment and improvement in wire assembly processes. Such ongoing reflection is crucial for the future of both sectors.

Top Wire Assemblies Applications in Modern Technology

Future Trends in Wire Assembly Technologies and Innovations

Wire assembly technologies are evolving rapidly. These advancements impact a range of industries, from automotive to consumer electronics. Innovative techniques and materials are shaping future applications. Lightweight materials enhance performance while reducing costs. Flexible wire assemblies are becoming crucial for modern designs.

Sustainability is also a growing concern. Eco-friendly materials are gaining traction. Manufacturers face challenges in sourcing these materials without sacrificing quality. The demand for high-speed connectivity drives the need for advanced wire assemblies. Innovations must keep pace with increasing digital requirements. This can create pressure on production processes.

The role of automation cannot be ignored. Robotics can improve efficiency but also bring new challenges. Integration of automation in wire assembly processes often requires rethinking design strategies. Companies must adapt to these changes or risk falling behind. Continuous improvement and adaptation are vital for thriving in this competitive landscape.

Related Posts

-

What is a Cable Harness? Exploring Its Role in Modern Connectivity and Industry Applications

-

Exploring Cable and Harness Assembly Innovations at the 138th China Import and Export Fair 2025

-

Understanding the Role of RF Cable Assemblies in Modern Communication Systems

-

Top Trends in Harness Assembly Techniques for 2025 You Need to Know

-

2025 Top Trends in Wire Cable Assembly: Essential Insights for Industry Professionals

-

Understanding Electrical Wiring Harnesses: Key Trends and Industry Insights for 2024