What is a Wire Assembly and How Does it Impact Your Electrical Connections

Wire assemblies are integral components in the vast landscape of electrical connections, serving as the backbone of numerous applications across various industries. The global market for wire assemblies is projected to reach USD 68.3 billion by 2025, driven by the rising demand for reliable connectivity solutions in sectors such as automotive, telecommunications, and consumer electronics. This surge underscores the critical role that wire assemblies play in ensuring efficiency and safety in electrical systems.

With the increasing complexity of modern electrical devices, the demand for high-quality wire assemblies has never been more pronounced. According to a report by the Research and Markets, the automotive segment alone is expected to witness significant growth, reflecting the industry’s shift towards electrification and advanced driver-assistance systems (ADAS). Wire assemblies not only facilitate robust electrical connections but also enhance the durability and performance of the systems they comprise. As technological advancements continue to reshape our connectivity needs, understanding the nuances of wire assemblies becomes essential for anyone involved in the design and implementation of electrical infrastructure.

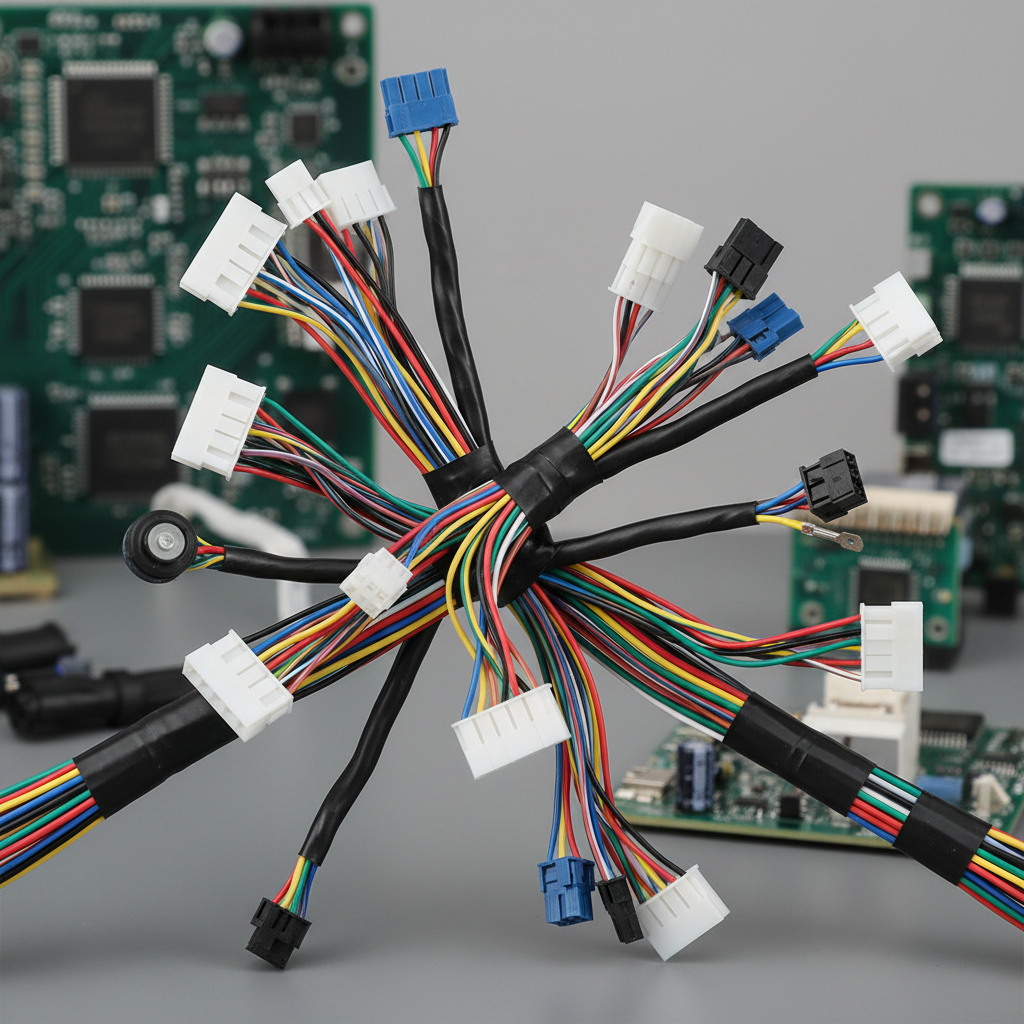

Understanding Wire Assemblies: Definition and Key Components

Wire assemblies are critical components in various electrical systems, serving as the connections that enable the flow of electricity.

At the core of an effective wire assembly are three key components: the wires themselves,

connectors, and protective insulation.

Wires are typically made of copper or aluminum, as these materials ensure optimal conductivity.

According to the International Wire & Cable Association (IWCA), the global wire and cable market is projected to reach approximately

$221 billion by 2026, underscoring the increasing demand for reliable wire assemblies in multiple sectors,

including automotive and aerospace.

Connectors play a vital role in wire assemblies, facilitating seamless communication between different electrical components.

They come in various forms, from simple splices to complex multi-pin connectors, with each type specifically designed to accommodate different

voltage and current requirements. A report by MarketsandMarkets forecasts that the global connectors market will grow from

$64.2 billion in 2021 to $82.2 billion by 2026,

highlighting the significant impact that advancements in connector technology have on the overall efficiency and reliability of wire assemblies.

Quality insulation ensures that these connections remain safe under various environmental conditions, preventing short circuits and electrical failures.

The Role of Wire Assemblies in Ensuring Robust Electrical Connections

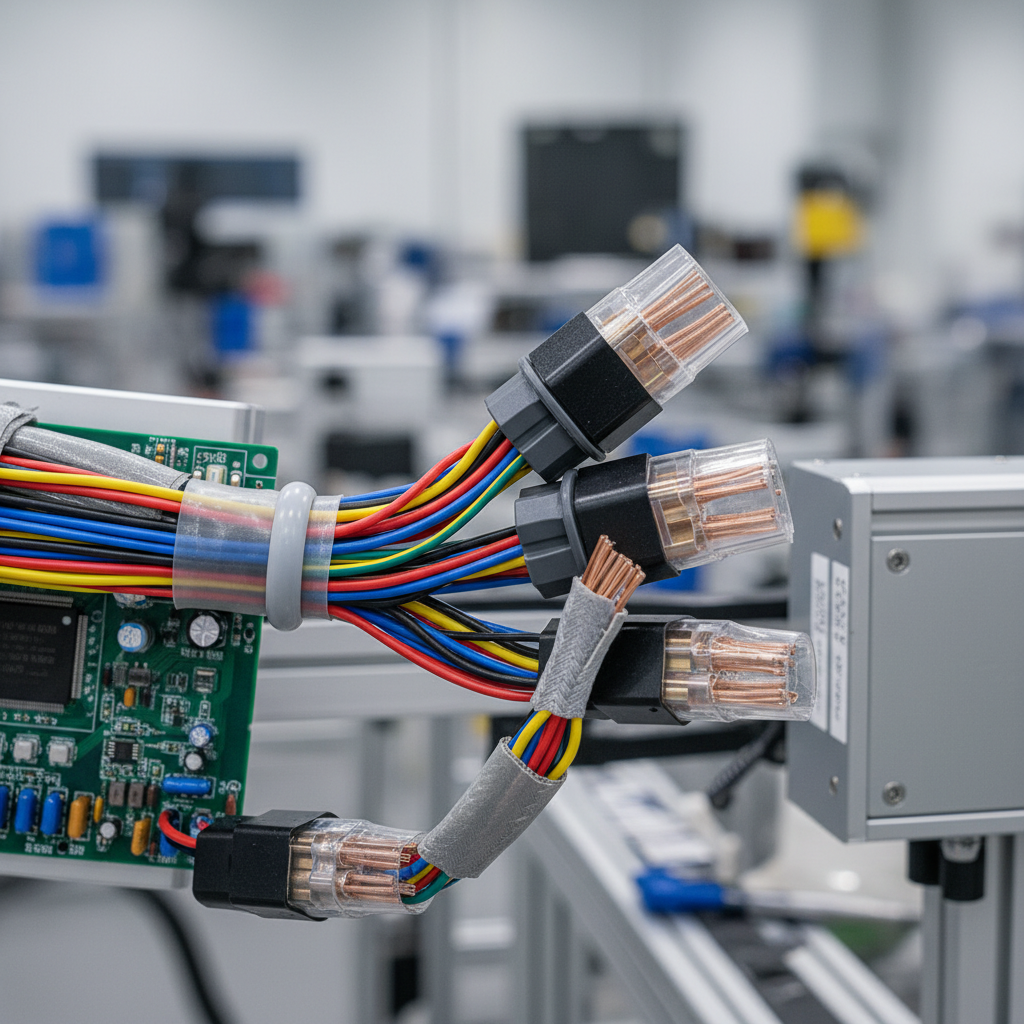

Wire assemblies play a crucial role in establishing reliable electrical connections across various industries. These assemblies consist of multiple wires and components that are bundled together, often including connectors and terminals, to create a streamlined and efficient electrical system. According to a report by the Electrical Wires Association, over 70% of electrical failures in systems can be traced back to poor connections, emphasizing the importance of robust wire assemblies in minimizing downtime and maintenance costs.

The quality and design of wire assemblies directly influence the performance and longevity of electrical systems. A well-constructed wire assembly can withstand environmental factors such as temperature fluctuations and exposure to moisture, which can degrade connection integrity. Data from the International Electrotechnical Commission indicates that high-quality wire assemblies can reduce signal loss by up to 15%, which is critical for applications requiring precise data transmission. Furthermore, advancements in materials and manufacturing processes have led to improved insulation and robustness, allowing for longer-lasting connections that meet stringent safety standards.

What is a Wire Assembly and How Does it Impact Your Electrical Connections - The Role of Wire Assemblies in Ensuring Robust Electrical Connections

| Dimension | Description | Impact on Electrical Connections |

|---|---|---|

| Material Type | Copper, Aluminum, or other conductive materials | Influences conductivity and resistance. |

| Wire Gauge | AWG standard measurement (American Wire Gauge) | Affects current carrying capacity. |

| Insulation Type | PVC, Teflon, Nylon, etc. | Provides safety and reduces short circuits. |

| Connection Type | Soldered, crimped, or terminal block connections | Determines reliability and ease of maintenance. |

| Environmental Rating | Designed for various conditions (moisture, heat, chemicals) | Ensures durability and functionality in specific environments. |

| Length of Wire | Measured in feet or meters | Can affect resistance and voltage drop. |

Impact of Wire Assembly Quality on System Reliability and Performance

The quality of wire assembly plays a crucial role in ensuring the reliability and performance of electrical systems. Well-constructed wire assemblies not only facilitate efficient electrical connections but also minimize the potential for failure. High-quality components, precise connections, and proper insulation can significantly reduce issues such as signal loss, overheating, and short circuits, which are common in poorly made assemblies. This is especially important in critical applications where system reliability is paramount, such as in aerospace, medical devices, and industrial machinery.

Moreover, the impact of wire assembly quality extends beyond immediate performance. It can affect the longevity of the entire electrical system, leading to reduced maintenance costs and increased operational uptime. In environments where systems are subjected to vibrations, temperature fluctuations, or exposure to harsh elements, using superior wire assemblies can mitigate these risks. As a result, investing in high-quality wire assemblies not only enhances system performance but also contributes to the overall safety and efficiency of operations.

Industry Standards and Regulations Governing Wire Assembly Production

Wire assembly is a critical component in electrical connections, and its production is governed by several industry standards and regulations designed to ensure safety, reliability, and performance. One of the most prominent standards is the IPC/WHMA-A-620, which provides the requirements for the acceptance of soldered and crimped connections in wire harness assemblies. This standard is essential for maintaining uniformity in production processes across the industry, as it outlines the criteria for workmanship and the materials used in assembly.

Additionally, the International Electrotechnical Commission (IEC) sets forth the IEC 60227 standard, which specifies the requirements for insulated wires and cables. Compliance with this standard is crucial for manufacturers, as it influences the quality and durability of wire assemblies, impacting electrical performance and safety. According to a report by Technavio, the global market for wire and cable assemblies is projected to grow by over 7% annually between 2021 and 2025, which underscores the significance of adhering to these standards. Ensuring that wire assemblies meet industry regulations not only enhances product quality but also helps manufacturers penetrate diverse markets while minimizing the risk of electrical failures.

Future Trends in Wire Assembly Technologies and Their Market Implications

The future of wire assembly technologies is poised to bring significant advancements that will enhance the efficiency and reliability of electrical connections. As the demand for more compact and efficient electronic devices increases, manufacturers are exploring innovative materials and methods that streamline the assembly process. For instance, the integration of automation and robotics in wire assembly can greatly reduce production time and minimize human error, resulting in higher quality products. Additionally, technologies such as 3D printing and custom connectors are emerging, allowing for more tailored solutions that can meet specific application needs.

Moreover, sustainability is becoming a focal point in wire assembly technologies. As industries strive to reduce their carbon footprints, the development of eco-friendly materials and processes is gaining momentum. This trend not only addresses environmental concerns but also aligns with consumer demands for greener products. Companies that embrace these innovations will likely position themselves favorably in the market, capitalizing on the growing consumer awareness around sustainability. Overall, the evolution of wire assembly technologies is set to impact not just the manufacturing field but also the broader market dynamics as businesses adapt to these emerging trends.

Impact of Wire Assembly on Electrical Connections

Related Posts

-

Explore Superior Wire Harness Assembly Solutions from Leading Chinese Manufacturers

-

The Definitive Ultimate Guide to Mastering Wire Harness Assembly for Optimal Performance

-

Challenges Faced in Cable Harness Design Efficiency

-

The Future of Cable and Harness Technology in Sustainable Energy Solutions

-

How to Choose the Right SMA Male Connector for Your Project

-

Essential Harness Assembly Checklist for Streamlined Production Efficiency