Top Wire Harness Manufacturing Equipment Trends to Watch in 2025

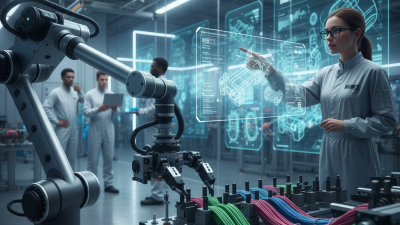

In the rapidly evolving landscape of the wire harness manufacturing equipment industry, staying abreast of trends is crucial for companies striving for efficiency and innovation. As we look towards 2025, experts like Dr. Emily Turner, a leading specialist in industrial automation, emphasize the importance of adaptation. She states, “The future of wire harness manufacturing equipment lies in our ability to integrate smart technologies that enhance productivity and precision.”

This integration includes advancements such as automation, artificial intelligence, and data analytics, which are transforming production lines and redefining operational standards. Companies are increasingly investing in these technologies to optimize their processes and reduce manufacturing costs. Moreover, the shift towards sustainability is also influencing equipment design and production methods, marking a significant change in how wire harnesses are manufactured.

As these trends unfold, manufacturers must prepare to not only adopt new technologies but also to anticipate the evolving demands of clients, especially in sectors such as automotive and aerospace. Being proactive in embracing these developments will ensure that companies remain competitive in an ever-changing market.

Emerging Technologies in Wire Harness Manufacturing Equipment

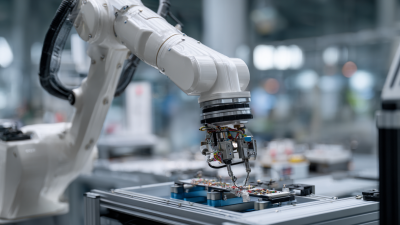

The wire harness manufacturing industry is poised for significant advancements in 2025, primarily driven by emerging technologies that enhance efficiency and precision. One trend to watch is the integration of automation and robotics. A report from Market Research Future estimates that the global market for industrial robotics in wire harness production will grow at a CAGR of 13.5% through 2025. These technologies not only streamline production processes but also reduce human error, resulting in higher-quality products.

Another notable trend is the adoption of smart manufacturing and the Internet of Things (IoT) in wire harness manufacturing equipment. According to a study by Research and Markets, the integration of IoT is anticipated to increase operational efficiency by up to 25%. This shift allows manufacturers to collect real-time data, making it easier to monitor production flow and conduct predictive maintenance, ultimately leading to decreased downtime and costs.

Tips: To stay ahead in the evolving landscape of wire harness manufacturing, consider investing in training programs for your workforce that focus on these emerging technologies. Additionally, collaborating with tech developers can provide insight into the latest innovations, fostering a culture of continuous improvement within your organization. By being proactive, manufacturers can adapt to these trends and optimize their production capabilities effectively.

Sustainability Trends Influencing Equipment Design and Production

As the wire harness manufacturing industry evolves, sustainability is progressively shaping equipment design and production processes. A recent report from MarketsandMarkets predicts that the wire harness market will reach USD 150 billion by 2025, with sustainability practices contributing significantly to this growth. Manufacturers are increasingly integrating eco-friendly materials into their product designs, opting for recyclable and biodegradable components to minimize environmental impact. This shift is not merely a response to regulatory pressures; it is a strategic move that aligns with consumer demand for greener solutions in technology and manufacturing.

Additionally, advancements in energy-efficient machinery are becoming a focal point in the industry's sustainability trend. According to TechNavio, the global green manufacturing market is expected to grow by over USD 25 billion between 2023 and 2027, driven by the adoption of less energy-intensive production techniques. Innovations such as smart manufacturing equipment, which utilizes IoT technologies, allow for real-time monitoring and optimization of energy consumption during the wire harness production process. This not only enhances productivity but also substantially reduces carbon footprints, making it an attractive investment for manufacturers aiming to bolster their sustainability credentials.

Overall, the integration of sustainable practices in wire harness manufacturing equipment is set to become a key differentiator in an increasingly competitive market, influencing future designs and operational methodologies. As manufacturers pivot towards sustainability, the industry may witness a transformative shift that prioritizes both environmental responsibility and operational efficiency.

Automation and Industry 4.0: Transforming Wire Harness Manufacturing

The wire harness manufacturing industry is poised for a significant transformation in 2025, driven largely by the adoption of automation and the principles of Industry 4.0. According to a recent report by MarketsandMarkets, the market for automation in manufacturing is expected to grow from $175 billion in 2021 to over $300 billion by 2026, highlighting a clear trend towards increased efficiency and productivity in various sectors, including wire harness production. This shift is crucial as manufacturers strive to reduce operational costs while enhancing quality and speed in their processes.

Automation technologies, such as robotic assembly systems and real-time data analytics, are redefining wire harness manufacturing by minimizing manual intervention and enabling predictive maintenance. A report from Grand View Research states that the global industrial automation market is projected to reach $510 billion by 2025, with wire harness manufacturers adopting these technologies to streamline workflows and foster greater flexibility in production. Enhanced data connectivity through IoT devices allows for improved monitoring of machinery, resulting in decreased downtime and optimized resource allocation, which is essential in meeting the rising demands for customized and high-quality wire harness solutions.

As the industry moves towards a more interconnected and automated future, companies are increasingly integrating smart manufacturing practices that not only increase efficiency but also promote sustainability. The shift towards smart factories, as highlighted by a study from Deloitte, indicates that approximately 70% of manufacturers are expected to embrace Industry 4.0 technologies by 2025, thereby enhancing their competitive edge in the wire harness market. The convergence of automation and advanced manufacturing is set to revolutionize the sector, paving the way for innovations that can significantly impact productivity and operational excellence.

Trends in Wire Harness Manufacturing Equipment (2025)

This chart illustrates the projected investment trends in various wire harness manufacturing equipment technologies for the year 2025. Automation is expected to receive the largest share of investment, followed by IoT integration and AI & Machine Learning technologies. The emphasis on sustainability practices is gaining traction, although currently, it represents a smaller percentage of overall investment.

Advanced Materials Impacting Wire Harness Equipment Efficiency

As the wire harness manufacturing industry evolves, the adoption of advanced materials has become a pivotal factor impacting the efficiency of wire harness equipment. By 2025, it is projected that approximately 50% of wire harness manufacturers will integrate high-performance materials such as thermoplastics and lightweight composites into their production processes. This shift not only enhances durability but also reduces the overall weight of wire harness assemblies, leading to improved fuel efficiency in automotive applications.

Moreover, reports indicate that the use of advanced materials can increase production speed by up to 30%, addressing the growing demand for quicker turnaround times in complex designs. Advanced materials exhibit superior thermal and electrical properties that can withstand extreme conditions, thus minimizing failures and maintenance costs. For instance, the automotive sector has witnessed a notable increase in demand for these materials, with the lightweight components market expected to reach $20 billion by 2025. This trend signifies a broader movement towards sustainability and efficiency in manufacturing practices, ultimately positioning companies to better meet evolving market needs while maintaining cost-effectiveness.

Challenges and Solutions in Adopting New Manufacturing Equipment

As the wire harness manufacturing industry evolves, companies face numerous challenges when adopting new equipment and technologies. Integrating cutting-edge machinery can be daunting, particularly due to high initial costs, the need for specialized training, and disruptions to existing workflows. Organizations must address these hurdles strategically to maximize their investment and ensure a smooth transition to advanced manufacturing processes.

Tips for overcoming these challenges include conducting thorough research to understand the potential return on investment, engaging employees in the transition process, and providing ample training to reduce resistance. By fostering an environment that embraces change, companies can mitigate the anxiety surrounding new equipment. Implementing pilot programs allows businesses to test new technologies on a smaller scale before full implementation, helping to identify potential issues early on.

Another key aspect of successful equipment adoption is maintaining open lines of communication within the organization. This helps ensure that all team members are informed and feel included in the transition process. Regular updates about the benefits of the new technology and acknowledgment of team efforts can also enhance morale and cooperation. By anticipating challenges and investing in support systems, wire harness manufacturers can position themselves for success in the ever-evolving landscape of manufacturing technology.

Related Posts

-

Understanding the Importance of SMA Male Connectors in Modern Technology Systems

-

Top Trends in Harness Assembly Techniques for 2025 You Need to Know

-

How to Select the Right Electrical Harness Connectors for Your Projects

-

Essential Harness Assembly Checklist for Streamlined Production Efficiency

-

2025 Top 10 Electrical Harness Assembly Innovations for Efficient Manufacturing

-

Innovative Applications of Molded Cable Assemblies Across Various Industries